Lit. No. 70451, Rev. 06

13

November 1, 2018

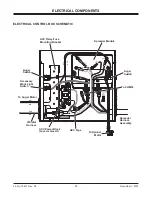

INSTALL HOPPER IN VEHICLE BED

NOTE: Periodically throughout the snow and ice

control season, verify that mounting devices

are secure.

1. If the spinner assembly has been stored inside

the hopper or is attached to the hopper, remove it

and set aside. Remove any debris from inside the

hopper.

2. Remove the vehicle tailgate.

3. Lift the spreader by all four large round holes on

the top of the diagonal corner rails (two shown

below), using slings or chains. Move the spreader

into the vehicle bed.

MOUNTING THE SPREADER

4. Adjust the spreader position to align the holes in

the hopper frame with the frame mounting holes in

the vehicle bed. If mounting holes are not already

drilled, refer to the hopper spreader Installation

Instructions for drilling instructions.

NOTE: Pay special attention when drilling or

clamping dissimilar metals to aluminum bodies.

Galvanic corrosion can occur if not handled

properly. Contact vehicle manufacturer for

recommended attachment practices.

5. Install the spreader to the vehicle bed using four

1/2" cap screws down through the spreader frame

and secure with 1/2" washers and 1/2" locknuts.

NOTE: If the mounting holes are not directly over

the vehicle box supports, the vehicle bed must

be braced to the frame to prevent buckling or

deforming the vehicle bed.

6. Install the frame spacer between the end of the

hopper frame and the front of the vehicle bed

as shown. If you do not have a spacer, refer to

the hopper spreader Installation Instructions for

directions on building one.

Failure to install this

spacer could result in damage to the spreader.

7. Connect the vehicle-side harness to the

hopper-side harness.

Install Tie-Down Ratchet Straps

Install ratchet straps from the large round holes on the

top of the diagonal corner rails of the spreader frame

diagonally outward to the vehicle frame.

CAUTION

Before lifting, verify that the hopper is empty

of material. The lifting device must be able to

support the spreader's weight as shown in

the spreader speci

fi

cations table.

Round Holes

(two per side)

Stop Bars

Frame Mounting

Holes

WARNING

Spreader shall be bolted to vehicle frame.

Do not rely on the tie-down chains or straps

alone to hold spreader in vehicle.

Frame Spacer

Built to Fit