Not for

Reproduction

12

800X Series Zero-Turn Rider - 61” & 72” Mower Deck

ferrismowers.com | snapperpro.com

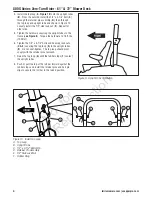

Figure 22. Checking the Deck Lift Rod Timing

These edges of the

rod pivots should be

straight up and down.

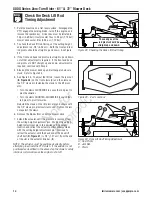

Figure 23. 2 x 4 Locations

Check the Deck Lift Rod

Timing Adjustment

1. Park the machine on a flat, level surface. Disengage the

PTO, engage the parking brake, turn off the engine, and

remove the ignition key. Drive tires must be inflated to

10 psi (0,69 bar); tractor caster tires to 25 psi (1,72 bar);

mower deck caster tires to 25 psi (1,72 bar).

2. To check the deck lift rod timing, set the cutting height

adjustment to 3-1/4” (8,26 cm). Both the front and rear

rod pivots should be straight up and down. See Figure

22.

3. If the front and back rod pivots are straight up and down,

no further adjustment is required. If the front and back

rod pivots are NOT straight up and down, adjustment is

required, continue with Step 4.

4. Block up the mower deck up until all hanger chains are

slack. Refer to Figure 23.

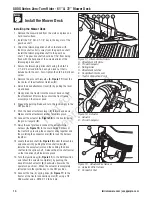

5. See Figure 24. To adjust the lift rod, loosen the jam nut

(

B, Figure 24

) on the front clevis (

C

) and then remove

the 1/2” clevis pin fastening the clevis to the lift pivot

arm.

• Turn the clevis CLOCKWISE to cause the rod pivot to

pivot backwards;

• Turn the clevis COUNTER-CLOCKWISE to cause the

rod pivot to pivot forwards.

Reinstall the clevis on the lift pivot arm and secure with

the 1/2” clevis pin previously removed. Tighten the jam

nut against the clevis.

6. Remove the blocks from under the mower deck.

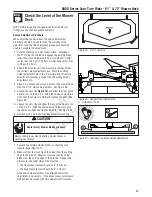

7. Extend the actuator until the pressure is removed from

the cutting height adjustment pin. Position the cutting

height adjustment pin in the desired cutting height

location and retract the actuator until contact is made

with the cutting height adjustment pin. Continue to

retract the actuator until the back end of the deck lift

shaft bolt (

D, Figure 21

) is 1/2” (1,27 cm) from the end

of the slot in the actuator link bar (

E

).

NOTE: The actuator must be positioned correctly before

attempting to activate the PTO clutch. If the actuator is not

positioned as described in the above step the mower’s safety

interlock system will cause the engine to shut off.

Figure 24. Deck Lift Rod Timing Adjustment

A. Rod Pivots

B. Jam Nut

C. Clevis

A

A

B

C