3

IMPORTANT SAFETY INSTRUCTIONS

PREPARATION

(Continued From Previous Page)

11.

Protect yourself when mowing and wear

appropriate clothing including safety glasses, long

pants, ear protection, hardhat and substantial

footwear with good traction. Long hair, loose

clothing or jewelry may get tangled in moving

parts.

12. Know how to STOP blades and engine quickly in

preparation for emergencies.

13. Use extra care when loading or unloading the

machine into a trailer or truck.

14. Check grass catcher components frequently for

signs of wear or deterioration and replace as

needed to prevent injury from thrown objects

going through weak or worn spots.

OPERATION

1. DO NOT put hands or feet near or under rotating

parts. Keep clear of the discharge area while the

engine is running.

2. BEFORE STARTING ENGINE, blades must be OFF

and Traction Levers LOCKED in the Traction Lock

position.

3. Stop Blades when crossing gravel drive, walks,

and under any conditions where thrown objects

might be a hazard.

4. DO NOT raise deck with the blades running.

5. Mow only in daylight or good artificial light.

6. USE EXTRA CARE when approaching blind

corners, shrubs, trees or other objects that may

obscure vision.

7. DO NOT operate the machine while under the

influence of alcohol or drugs.

8. After striking a foreign object or if the mower

vibrates abnormally, STOP the blades and engine.

Remove the key. Disconnect and secure the spark

plug wire. Inspect the mower for any damage and

repair the damage.

9. DO NOT operate machine near drop offs, ditches,

embankments, washouts culverts, fences and

protruding objects. STAY ALERT for holes and

other hidden hazards. Tall grass can hide

obstacles.

10. DO NOT operate machine on wet grass. Always be

sure of your footing while operating machine,

especially while backing up. Keep a firm grip on

the handle. Walk: never run. Slipping and falling

could cause injury.

11. DO NOT leave the machine with the engine

running. STOP BLADES, STOP ENGINE and

REMOVE KEY before leaving the operator position

for any reason.

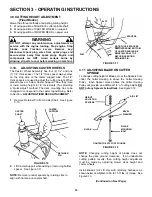

OPERATION

(Continued From Previous Column)

10. Before cleaning, repairing, or inspecting make

certain blades, engine and all moving parts have

STOPPED. Remove key and secure spark plug

wire away from spark plug key to prevent

accidental starting.

11. STOP MACHINE on level ground, engage

parking brake (if equipped) and make sure engine

and blades have stopped before leaving the

operator’s position for any reason including

removing grass catcher or unclogging mower to

prevent injury to hands or feet.

12. Blades must be OFF except when cutting

grass. Set blades in highest position when

mowing over rough ground.

13. Keep hands and feet away from rotating

blades underneath deck.

14. DO NOT operate machine without entire grass

catcher or guards in place. DO NOT point

discharge at people, passing cars, windows or

doors.

15. Slow down before turning.

16. Watch out for traffic when near or crossing

roadways.

17. Move motion control levers SLOWLY to

maintain control during speed and directional

changes.

18. DO NOT operate engine in enclosed areas.

Engine exhaust gases contain carbon monoxide, a

deadly poison.

MAINTENANCE

1. Shut off fuel while storing or transporting. DO

NOT store machine or fuel container inside where

fumes may reach an open flame, spark or pilot

light such as in a water heater, furnace, clothes

dryer or other gas appliance. Allow engine to cool

before storing machine in an enclosure. Store fuel

container out of the reach of children in a well

ventilated, unoccupied building.

2. Clean grass and debris from engine, mufflers,

drives and cutting units to help prevent fires.

Clean up fuel, oil and excess grease.

3. When draining fuel tank, drain fuel into an

approved container outdoors and away from open

flame.

4. Check brakes frequently (if equipped); adjust,

repair or replace as needed.

5. Keep all bolts, nuts and screws properly tight.

Check that all cotter pins are in proper position.

6. Always provide adequate ventilation when running

engine. Exhaust gases contain carbon monoxide,

an odorless and deadly poison.

Summary of Contents for SPE361

Page 8: ...8 SECTION 2 SAFETY MESSAGES AND SYMBOLS IMPORTANT SAFETY AND OPERATING INSRUCTIONS...

Page 26: ...26 SECTION 8 ELECTRICAL FIGURE 8 1...

Page 28: ...28 PRIMARY MAINTENANCE...

Page 29: ...29 PRIMARY MAINTENANCE...

Page 30: ...30 PRIMARY MAINTENANCE...

Page 31: ...31 PRIMARY MAINTENANCE...

Page 32: ...32 NOTES...

Page 33: ...33 NOTES...