21

SECTION 5 - ADJUSTMENTS

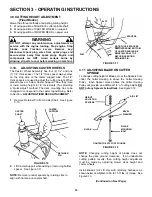

5.3 HANDLE HEIGHT

The operator handle can be adjusted for operator

comfort as follows:

1. Loosen the upper carriage bolt and nut on both left

and right lower handles. See Figure 5.3.

2. Remove lower carriage bolt and nut from both left

and right handles.

3. Raise or lower handlebar to desired height. See

Figure 5.3.

4. Align handle with one of the adjustment holes in the

tank support bracket and insert the carriage bolt.

See Figure 5.3.

5. Verify that the handle is still at desired height. Using

nuts removed in Step 2, tighten both lower carriage

bolts securely.

6. Securely tighten both upper carriage bolts and nuts.

7. The Traction Levers will require adjustment after the

handle height has been adjusted. Refer to Section

“ADJUSTMENTS – Traction Levers/Rods”.

8. The Transmission Shift Lever linkage will require

adjustment after the handle height has been

adjusted. Refer to Section “ADJUSTMENTS –

Transmission Shift Lever”.

FIGURE 5.3

5.4 TRANSMISSION SHIFT LEVER

ADJUSTMENT

1. Disconnect the hair pin from shift rod that connects

to the Transmission Shift lever. See Figure 5.4.

2. Move the Transmission Shift lever to the neutral

position. Move the shift lever, located on the

transmission, to the neutral position.

3. Rotate the shift rod clockwise or counter clockwise to

allow the upper portion of shift rod to be inserted into

the Transmission Shift lever without moving the

speed control lever or the transmission shift lever.

Reinstall hair pin. See Figure 5.5.

FIGURE 5.4

FIGURE 5.5

RAISE

LOWER

LOOSEN

UPPER

CARRIAGE

BOLT

REMOVE

LOWER

CARRIAGE

BOLT

TRANSMISSION

SHIFT

LEVER

DISCONNECT

SHIFT ROD

FROM THIS

POINT

SHIFT

ROD

SHIFT

LEVER

SHIFT

ROD

ROTATE

SHIFT

ROD

Summary of Contents for SPE361

Page 8: ...8 SECTION 2 SAFETY MESSAGES AND SYMBOLS IMPORTANT SAFETY AND OPERATING INSRUCTIONS...

Page 26: ...26 SECTION 8 ELECTRICAL FIGURE 8 1...

Page 28: ...28 PRIMARY MAINTENANCE...

Page 29: ...29 PRIMARY MAINTENANCE...

Page 30: ...30 PRIMARY MAINTENANCE...

Page 31: ...31 PRIMARY MAINTENANCE...

Page 32: ...32 NOTES...

Page 33: ...33 NOTES...