16

SECTION 3 - OPERATING INSTRUCTIONS

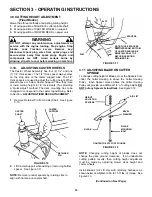

3.9 CUTTING HEIGHT ADJUSTMENT

(Fixed

Decks)

Mower has three methods of adjusting cutting height:

1. Moving position of BLADE on cutter spindle shaft.

2. Moving position of CASTER WHEEL on support.

3. Moving position of MOWER DECK on power unit.

WARNING

DO NOT attempt any maintenance, adjustments or

service with the engine running. Stop engine. Stop

blades. Lock Traction Levers. Remove key.

Disconnect spark plug wires from spark plugs and

secure wires away from spark plugs. Engine and

components are HOT. Avoid serious burns by

allowing all parts to cool before working on machine.

3.10. ADJUSTING

CASTER WHEELS

The Caster Wheel Assembly has four (4) 1/2” and one

(1) 1/4” thick spacer. The 1/4” thick spacer always stays

on the stop side of the caster support tube. The 1/2”

thick spacers are used to adjust the cutting height. When

placed above or below Caster Support Tube, they raise

or lower cutting height in 1/2” increments, thus providing

a “Quick-Adjust” method. The deck mounting has to be

changed to correspond to the caster repositioning. Refer

to Section, “ADJUSTING FIXED DECK ATTACHMENT”.

1. Remove Retainer Pin from Caster Shaft. See Figure

3.10.

FIGURE 3.10

2. Lift Caster Support while adding or removing bottom

spacer. See Figure 3.11.

NOTE: Remove (or add) spacers by rotating slots to

align with flat area on caster shaft.

FIGURE 3.11

3.11 ADJUSTING BLADE ON CUTTER

SPINDLE

To change cutting height of Blades, move the Spacers from

under the Cutter Housing to above the Cutter Housing

Pulley. Each Spacer moved above the Cutter Housing

Pulley will provide an additional 1/4” of cutting height. DO

NOT put any Spacers below Blade. See Figure 3.12.

FIGURE 3.12

NOTE: Changing cutting height of blades does not

change the deck ground clearance. If an undesirable

cutting pattern results, then cutting height adjustment

must be made by adjusting mower deck height and

caster wheels.

Install Blades (Air Lift Up) with retaining hardware as

shown below and tighten to 60 to 75 ft. lbs. of torque. See

Figure 3.13.

(Continued on Next Page)

CASTER

SHAFT

CASTER

SUPPORT

RETAINER

PIN

SLOT

SPACERS

FLAT

NOTE: THOSE SPACERS

REMOVED FROM BOTTOM

OF CASTER SHOULD BE

REINSTALLED AT TOP

BEFORE INSERTING

RETAINER PIN.

HEIGHT

ADJUSTING

SPACERS

AIR LIFT

BEVEL

WASHER

BLADE

BLADE

MOUNTING

BOLT

TIGHTEN TO 60-75 FOOT POUNDS

Summary of Contents for SPE361

Page 8: ...8 SECTION 2 SAFETY MESSAGES AND SYMBOLS IMPORTANT SAFETY AND OPERATING INSRUCTIONS...

Page 26: ...26 SECTION 8 ELECTRICAL FIGURE 8 1...

Page 28: ...28 PRIMARY MAINTENANCE...

Page 29: ...29 PRIMARY MAINTENANCE...

Page 30: ...30 PRIMARY MAINTENANCE...

Page 31: ...31 PRIMARY MAINTENANCE...

Page 32: ...32 NOTES...

Page 33: ...33 NOTES...