12

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool. Wear heavy leather gloves when

handling or working around cutting blades. Blades

are extremely sharp and can cause severe injury.

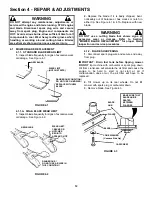

4.1 MOWER BLADE REPLACEMENT

4.1.1. STANDARD BLADE WEAR LIMIT

1. Inspect blade frequently for signs of excessive wear

or damage. See Figure 4.1.

FIGURE 4.1

4.1.1.A. NINJA BLADE WEAR LIMIT

1. Inspect blade frequently for signs of excessive wear

or damage. See Figure 4.2.

FIGURE 4.2

2. Replace the blade if it is badly chipped, bent,

noticeably out of balance or has cracks or notch in

either tip. See Figure 4.1 & 4.1A. Replace with new

blade.

WARNING

DO NOT use a cutting blade that shows signs of

excessive wear or damage. Refer to Section

“MOWER BLADE REPLACEMENT” for proper blade

inspection and service procedures.

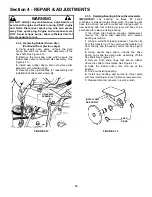

4.1.2. BLADE SHARPENING

1. Disconnect spark plug wire and secure end away

from plug.

IMPORTANT: Drain fuel tank before tipping mower.

DO NOT tip machine with carburetor or spark plug down.

Oil from crankcase will saturate the air filter and cause the

engine to be hard to start or not start at all. If

contamination does occur, the air filter will have to be

replaced.

2. Tilt mower up on its rear wheels. Do not tilt

mower with spark plug or carburetor down.

3. Remove blade. See Figure 4.3.

FIGURE 4.3

BLADE

HUB

MAKE SURE THAT

BLADE HUB IS

SEATED

BETWEEN

FLANGES

FLANGE

BLADE

CONE WASHER

(Concave Side Up)

CAPSCREW

NEW BLADE

WEAR LIMIT

(NOTCH STARTS)

DANGEROUS CONDITION !

DO NOT USE ON MOWER !

REPLACE WITH NEW

BLADE.

NEW BLADE

WEAR LIMIT.

CRACKS OR

NOTCHES

BEGIN TO

APPEAR ON TIP

DANGEROUS !

DO NOT USE A BLADE IN

THIS CONDITION !

Summary of Contents for FRP2167517BV

Page 22: ...22 PRIMARY MAINTENANCE...

Page 23: ...23 PRIMARY MAINTENANCE...

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...