11

Section 3 – MAINTENANCE

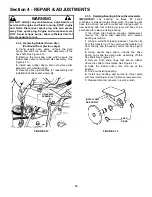

3.2.2. CHECK GREASE LEVEL IN TRANSMISSION

(Continued from previous page)

NOTE: Do not spill grease or oil on surface of drive disc.

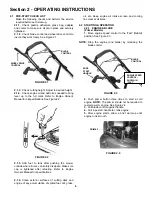

See Figure 3.3.

3. Reinstall transmission plug.

4. Check grease level after each 25 hours of

operation.

FIGURE 3.3

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for

all components to cool. Wear heavy leather gloves

when handling or working around cutting blades.

Blades are extremely sharp and can cause severe

injury.

IMPORTANT: Drain fuel tank before tipping mower.

DO NOT tip machine with carburetor or spark plug down.

Oil from crankcase will saturate the air filter and cause the

engine to be hard to start or not start at all. If

contamination does occur, the air filter will have to be

replaced.

3.2.3. CHECK MOWER BLADE

1. Disconnect spark plug wire and secure end away

from plug.

2. Tilt mower up on its rear wheels for access to

the blade cap screw. Do not tilt mower with spark

plug or carburetor down. See Figure 3.4.

3. Check torque of blade retaining cap screw.

Recommended torque should be 40 ft. lbs. See

Figure 3.4.

4. Check blade for sharpness, wear and damage.

Refer to Section “Blade Wear Limits”.

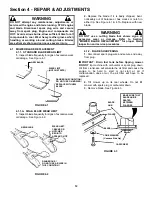

3.2.4. CHECK ENGINE DRIVE BELT

1. Visually check engine drive belt for cracking,

fraying, severed or belt strands exposed. If worn or

damaged, replace belt before operating mower.

3.2.5. CHECK TRANSMISSION POLY-V BELT

1. Visually check poly-v belt for cracking, fraying,

severed or belt strands exposed. If worn or

damaged, replace belt before operating mower.

FIGURE 3.4

3.3 SERVICE - ANNUALLY

Perform all maintenance as described in the “Service

Schedule” section of this manual.

3.3.1. Engine

Service engine according to engine owner’s manual.

3.3.2. Air

Filter

Refer to engine owner’s manual for service instructions.

3.3.3. Engine

Oil

Refer to engine owner’s manual for service instructions.

3.4 STORAGE

PROCEDURE

Refer to the Engine Owner’s Manual for directions regarding

engine storage preparations. Prepare the mower for “end of

season” storage as follows:

1. Drain fuel from fuel tank and let engine run until all fuel is

out of the carburetor.

2. Disconnect and remove the spark plug wire away

from spark plug before any other preparations are

made!

3. Tape all openings closed to prevent spraying water into

exhaust or air intakes during washing.

4. Tilt mower up on its rear wheels and thoroughly clean

the underside of the deck. Do not tilt mower with spark plug

or carburetor down. Scrape away any accumulation of

grass with a putty knife and or wire brush.

5. Lubricate all exposed metal with a light coating of oil to

prevent corrosion.

6. On self-propelled models disconnect transfer rod clip

and remove ground speed control rod before folding

handles.

7. Loosen handle knobs. Carefully fold the handles

forward, “flexing” the control cables to prevent cable

damage.

8. Store the mower in a shed or other dry area, protected

from weather.

KEEP DRIVE DISC CLEAN!

RECOMMENDED

BLADE RETAINING

CAP SCREW

TORQUE VALUE

SHOULD BE 40 FT.

LBS.

Summary of Contents for FRP2167517BV

Page 22: ...22 PRIMARY MAINTENANCE...

Page 23: ...23 PRIMARY MAINTENANCE...

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...