8

Section 2 - OPERATING INSTRUCTIONS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

2.6 RECYCLING

OPERATION

NOTE: For best recycling results, cut up to a maximum of

1/3 of grass blade length and recycle ONLY when grass is

dry.

1. Set all wheels in the highest cutting position

(Notch 6).

2. Move engine speed control to “FAST” (Rabbit)

position.

3. Move ground speed control to slowest speed

setting.

4. Proceed mowing slowly. If grass is very dense,

lower each rear wheel latch one notch lower than

the front wheel latches to improve recycling

performance.

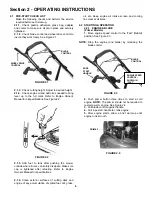

2.7 ADJUSTING FRONT DECK BAFFLE

The front of the cutting deck on these models has been

modified with an open area. This allows the blade to

have more direct contact with the grass and allows

more air flow into deck chamber. The adjustable baffle

should be secured in the lowest position when using a

grass bag. The baffle should be secured in the highest

position when mulching grass.

NOTE: Under certain conditions, when mulching, some

grass may blow out from under front of baffle. This is

normal but, the amount of grass blowing out can be

reduced. Lower baffle slightly to reduce the amount of

grass blow out.

1. Stop engine.

2. Loosen wing nuts that secure front deck baffle.

See Figure 2.9.

3. Lower the adjustable baffle to the lowest position

when using a grass bag. Raise the baffle to its

highest position when mulching grass. Take care to

keep the baffle’s lower edge parallel to the bottom of

the deck. See Figure 2.9.

4. Retighten wing nuts securely.

WARNING

DO NOT operate without entire Grass Catcher or

guard in place. Grass Catcher components are

subject to deterioration during normal use. Inspect

frequently and replace worn or damaged components

immediately.

FIGURE 2.9

2.8 INSTALLATION of GRASS CATCHER

(Optional Accessory)

Install grass catcher by sliding connector over flange of

adapter. See Figure 2.10. Attach grass bag hooks over

middle handle cross bar. See Figure 2.11.

FIGURE 2.10

FIGURE 2.11

HOLE DESIGNATES TOP OF

BAFFLE (ALWAYS KEEP

HOLE IN UP POSITION)

FRONT DECK BAFFLE (SHOWN

IN HIGHEST POSITION)

FRONT

DECK

BAFFLE

WING

NUTS

MOVE BAFFLE UP FOR

MULCHING GRASS

MOVE BAFFLE DOWN

FOR GRASS BAGGING

FRONT CUTOUT OF DECK

WING NUT

POSITION BAG

BETWEEN HANDLES

SLIDE

CONNECTOR

DOWN OVER BAG

ADAPTER FLANGE

BAG

ADAPTER

CONNECTOR

ATTACH BAG HOOKS

OVER MIDDLE HANDLE

CROSS BAR

MIDDLE

HANDLE

CROSS

BAR

Summary of Contents for FRP2167517BV

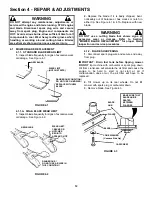

Page 22: ...22 PRIMARY MAINTENANCE...

Page 23: ...23 PRIMARY MAINTENANCE...

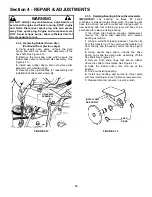

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...