Chapter 12

Tooling Installation and Work Holding

Installing and Changing Tools

WARNING

: Be sure the power is turned off and the machine unplugged

before installing or changing tool bits

Aligning Tooling -

Use the procedure below to align your tooling in the R-8

spindle:

Step 1: Select the appropriate tool or fixture.

Step 2: Wipe the surfaces of the tooling and spindle interior to ensure a

proper fit. Grease or debris on either surface will cause misalignment.

Step 3: Align the keyway in your tooling with the key inside the mill spindle

and insert the fixture in the lower mill spindle opening.

You can feel the key in the mill spindle with your finger. It is located just

beyond the tapered portion of the spindle.

Securing R-8 Tooling with the Drawbar -

Use the procedure below for

attaching and securing the drawbar:

Step 1: Remove the arbor bolt cover located on the top of the mill belt cover

and insert a drawbar (SAE standard 7/16-20) from the top of the spindle.

Step 2: Tighten the drawbar clockwise into the fixture or tooling that is

inserted into the mill spindle opening. Use the spanner wrench to stabilize

the spindle while tightening the drawbar.

Step 3: Use a wrench to apply torque to the drawbar. This will draw the

fixture firmly into the spindle.

Step 4: Reinstall the arbor bolt cover when the fixture/tooling is in place.

Removing R-8 Tooling from the Drawbar

Use the procedure below to remove tooling using the drawbar method:

Step 1: Stabilize the drawbar with the spanner wrench and use a wrench to

apply force counter clockwise to the drawbar nut.

Step 2: Loosen the drawbar two to three turns counter clockwise.

Step 3: Use a dead blow or brass hammer to strike a downward blow on the

top of the drawbar to loosen the fixture from the spindle.

Unscrew the drawbar only two to three turns before striking. Unscrewing it

further before striking the drawbar can damage the threads on the drawbar

or the fixture.

Step 4: Continue turning the drawbar until it unscrews from the tooling.

Step 5: After the tool is free from the spindle, hold the fixture with your free

hand or use a catch box to prevent the tooling from dropping onto your

machine or work piece.

28

Summary of Contents for MI-409MZ

Page 1: ...Smithy MI 409MZ Operator s Manual 1 ...

Page 31: ...Chapter 13 Parts Diagrams in work ...

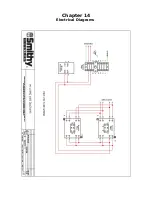

Page 32: ...Chapter 14 Electrical Diagrams ...

Page 33: ......