97

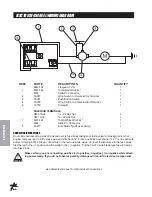

Accessories

INSTALLATION INSTRUCTIONS

Safety: Before working on machine stop engine, set park brake, remove key from ignition and block

wheels. Disconnect negative (-) battery terminal.

BOX MOUNT

Mount the switch box to the lower center of the dashboard. Remove the two phillips head bolts. Reinstall the #10

x 1 phillips head bolts and lockwashers to hold the switchbox onto the dashboard. Tighten all bolts.

WIRING

Use dielectric grease on all electrical connections. Connect power cable (15-509) to the switch box. Turn the

switch off. Route the power wire down through the grommet in the dashboard. Follow the wire harness down

under the floorboard, then back along the main frame and up to the fuse block in the engine compartment behind

the passenger seat. The power cable will need to be cut and shortened. Attach slide-on terminals to the wire

ends with heat shrink, then connect to fuse block. Red to po), black to negative(-). Insert 10 AMP fuse

into slot which has red wire attached to it.

Route Control Harness (15-504) from switch box on dashboard same as the power wire. Only continue all the

way to the rear of the machine. Then pull the cable up over the back of the spray tank so it can be connected to

the compressor.

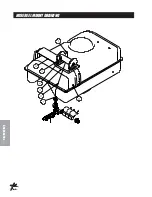

CONNECTING THE CAP ASSEMBLY

Connect the blue tube to the tank cap connector which is also connected to the large blue tube which hangs

below the cap. This is the soap outlet tube. Connect the clear tube to the other connector on the tank cap. This

is the air input tube. Tighten connectors hand tight, assembly tank cap onto tank.

HOSES

Being careful not to cut the tubing, cut the oversleeve back approximately 2" (5 cm) to expose blue and clear

tubing. Remove blue wing nut from top connector of foam nozzle and slide it on the blue tube with the threads

facing toward end of tube. Slide blue tube all the way over the top of the small tube on foam nozzle. Slide wing

nut back to the threads and hand tighten. Follow the same steps for the clear tube and tube nut.

Route the tubing along underside of main frame using tie downs as necessary.

Install opposite ends of air-liquid tubes to compressor, again cutting back the oversleeve approximately 2" (5 cm)

and inserting blue and clear tubes for the left boom section into the tubing connectors on the right side of com-

pressor as far as possible. Follow the same steps for the right boom tubing. Notice the right boom is inserted

into left side of compressor. To release tubing from compressor, hold black ring around tubing, and pull tube out.

Summary of Contents for 30-000-C

Page 13: ...11 Service NOTES ...

Page 18: ...16 Parts BODY FRAMEDRAWING ...

Page 20: ...18 Parts NOSECONEDRAWING ...

Page 22: ...20 Parts NOSECONEDRAWING ...

Page 24: ...22 Parts LINKAGEDRAWING ...

Page 26: ...24 Parts FRONTAXLEDRAWING ...

Page 28: ...26 Parts OIL FUELTANKDRAWING ...

Page 30: ...28 Parts SEATPANELDRAWING ...

Page 32: ...30 Parts ENGINEANDPUMPS DRAWING ...

Page 34: ...32 Parts ENGINEANDPUMPS DRAWING ...

Page 36: ...34 Parts COOLERANDEXHAUSTDRAWING ...

Page 38: ...36 Parts REARWHEELDRIVEDRAWING ...

Page 40: ...38 Parts TANKDRAWING ...

Page 42: ...40 Parts TURBO QUADAGITATORDRAWING ...

Page 44: ...42 Parts 15 301ORBITROLDRAWING ...

Page 48: ...46 Parts 30 102EATONPUMPDRAWING ...

Page 50: ...48 Parts 30 102EATONPUMPDRAWING ...

Page 52: ...50 Parts 30 101EATONMOTORDRAWING ...

Page 54: ...52 Parts 30 099 AUBURN POWERWHEEL DRAWING ...

Page 56: ...54 Accessories 3182PLUMBINGDRAWING RAVEN440 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Page 58: ...56 Accessories 3184PLUMBINGDRAWING RAVEN203 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Page 66: ...64 Accessories CONTROLS3182SYSTEMDRAWING RAVEN 440 ...

Page 68: ...66 Accessories CONTROLS3184SYSTEMDRAWING RAVEN 203 ...

Page 70: ...68 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER W RATE SYNC ...

Page 72: ...70 Accessories WIRING3187 3188SYSTEM RAVEN440 SHARPSHOOTER ...

Page 76: ...74 Accessories 15 743MANIFOLDVALVEDRAWING ...

Page 78: ...76 Accessories 17 58020 HEAVYBOOM ...

Page 80: ...78 Accessories 17 58020 BOOMDRAWING ...

Page 84: ...82 Accessories 17 585 18 HEAVYBOOM ...

Page 86: ...84 Accessories 17 585 18 HEAVYBOOM ...

Page 90: ...88 Accessories 30 010ELECTRICHOSEREELDRAWING ...

Page 94: ...92 Accessories HOSEREELMOUNT DRAWING ...

Page 96: ...94 Accessories 30 004FOAMMARKERDRAWING WIRINGDRAWING ...

Page 98: ...96 Accessories 30 004FOAMMARKERDRAWING ...

Page 100: ...98 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING ...

Page 103: ...101 Accessories NOTES ...

Page 106: ...104 Accessories 30 006FRESHWATERTANKDRAWING ...

Page 110: ...108 Accessories 15 620CHEMICALCLEANLOAD PARTSDRAWING ...