93

Accessories

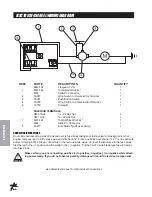

HOSE REEL MOUNT PARTS LIST

REF#

PART#

DESCRIPTION

QUANTITY

1

15-749

Hose Barb

3

/

4

1

2

8887-110

3

/

4

" Orange PVC Hose 110"

1

18-040

Hose Clamp

2

3

16-129

Manual Rewind Hose Reel

1

4

HB-516-18-150

Bolt

5

/

16

-18 x 1

1

/

2

4

HW-516

Washer

5

/

16

4

HNTL-516-18

Lock Nut

5

/

16

- 18

4

5

16-295

Hose Fitting

3

/

4

1

6

30-110

Hose Reel Mount bracket

(part of machine)

1

7

18-249

Barb Fitting

1

8

HB-516-18-175

Bolt,

5

/

16

-18 x 1

3

/

4

(part of machine)

4

HNFL-516-18

Flange Lock Nut,

5

/

16

- 18

(part of machine)

4

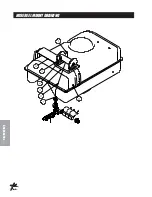

1. Wear protective clothing when draining the tank and taking apart the lines.

2. Drain tank and spray system in a safe and approved method insuring that no chemical or water remain

in tank as you will be taking apart lines.

3. Remove key from ignition, set park brake and block wheels.

4. Put hose reel on hose reel bracket with fitting to the rear of machine. Use four bolts

5

/

16

- 18 x 1

1

/

2

and four

5

/

16

- 18 lock nuts to hold in place. Tighten bolts.

5. Put 18-249 barb fitting into hose reel side.

6. Place the 16-295 Hose Fitting into the Hose reel center.

7. Remove the blank cover from the ball valve by the manifold valve and place the 15-749 Hose Barb.

Tighten clamp.

8. Route hose from the hose barb on the ball valve to the barb fitting on the side of the hose reel. Hold in

place with the two 18-040 clamps.

9. Be sure all clamps and hardware are tight before using.

HOSE REEL ADJUSTMENTS

OPERATIONAL CHECK:

1.

Pull hose off drum at least one full revolution. A clicking noise should be heard from locking mechanism.

2.

Let the hose retract.

3.

Pull the hose off until the first click is heard. Drum should lock when the hose tension is removed.

4.

Continue pulling the hose, no more than one revolution, until no clicking is heard. Hose should rewind when

tension is removed.

HOSE REPLACEMENT PROCEDURE:

1.

Facing swivel, turn the hose drum clockwise until all of the hose is removed from the drum and the drum is held by

locking mechanism. Make sure spring is locked.

2.

Remove hose clamps and disconnect hose from swivel. Remove old hose.

3.

Insert new hose through roller guide, connect to swivel and reinstall hose clamps. Use spring guard over hose to

protect the hose from being cut by the drum.

4.

Remove check ball from old hose and install on replacement hose.

5.

Carefully, keeping the tension on the hose, pull the hose to release the locking mechanism. Let the hose wind on

the drum.

Summary of Contents for 30-000-C

Page 13: ...11 Service NOTES ...

Page 18: ...16 Parts BODY FRAMEDRAWING ...

Page 20: ...18 Parts NOSECONEDRAWING ...

Page 22: ...20 Parts NOSECONEDRAWING ...

Page 24: ...22 Parts LINKAGEDRAWING ...

Page 26: ...24 Parts FRONTAXLEDRAWING ...

Page 28: ...26 Parts OIL FUELTANKDRAWING ...

Page 30: ...28 Parts SEATPANELDRAWING ...

Page 32: ...30 Parts ENGINEANDPUMPS DRAWING ...

Page 34: ...32 Parts ENGINEANDPUMPS DRAWING ...

Page 36: ...34 Parts COOLERANDEXHAUSTDRAWING ...

Page 38: ...36 Parts REARWHEELDRIVEDRAWING ...

Page 40: ...38 Parts TANKDRAWING ...

Page 42: ...40 Parts TURBO QUADAGITATORDRAWING ...

Page 44: ...42 Parts 15 301ORBITROLDRAWING ...

Page 48: ...46 Parts 30 102EATONPUMPDRAWING ...

Page 50: ...48 Parts 30 102EATONPUMPDRAWING ...

Page 52: ...50 Parts 30 101EATONMOTORDRAWING ...

Page 54: ...52 Parts 30 099 AUBURN POWERWHEEL DRAWING ...

Page 56: ...54 Accessories 3182PLUMBINGDRAWING RAVEN440 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Page 58: ...56 Accessories 3184PLUMBINGDRAWING RAVEN203 15 818 75 Fitting O ring 15 817 50 Fitting O ring ...

Page 66: ...64 Accessories CONTROLS3182SYSTEMDRAWING RAVEN 440 ...

Page 68: ...66 Accessories CONTROLS3184SYSTEMDRAWING RAVEN 203 ...

Page 70: ...68 Accessories WIRING 3185 3186 SYSTEM ENVIZIO PRO II SHARP SHOOTER W RATE SYNC ...

Page 72: ...70 Accessories WIRING3187 3188SYSTEM RAVEN440 SHARPSHOOTER ...

Page 76: ...74 Accessories 15 743MANIFOLDVALVEDRAWING ...

Page 78: ...76 Accessories 17 58020 HEAVYBOOM ...

Page 80: ...78 Accessories 17 58020 BOOMDRAWING ...

Page 84: ...82 Accessories 17 585 18 HEAVYBOOM ...

Page 86: ...84 Accessories 17 585 18 HEAVYBOOM ...

Page 90: ...88 Accessories 30 010ELECTRICHOSEREELDRAWING ...

Page 94: ...92 Accessories HOSEREELMOUNT DRAWING ...

Page 96: ...94 Accessories 30 004FOAMMARKERDRAWING WIRINGDRAWING ...

Page 98: ...96 Accessories 30 004FOAMMARKERDRAWING ...

Page 100: ...98 Accessories FOAMER NOZZLEMOUNT HOSEGUARDMOUNTDRAWING ...

Page 103: ...101 Accessories NOTES ...

Page 106: ...104 Accessories 30 006FRESHWATERTANKDRAWING ...

Page 110: ...108 Accessories 15 620CHEMICALCLEANLOAD PARTSDRAWING ...