-107-

No. JXC

※

-OMT0002-C

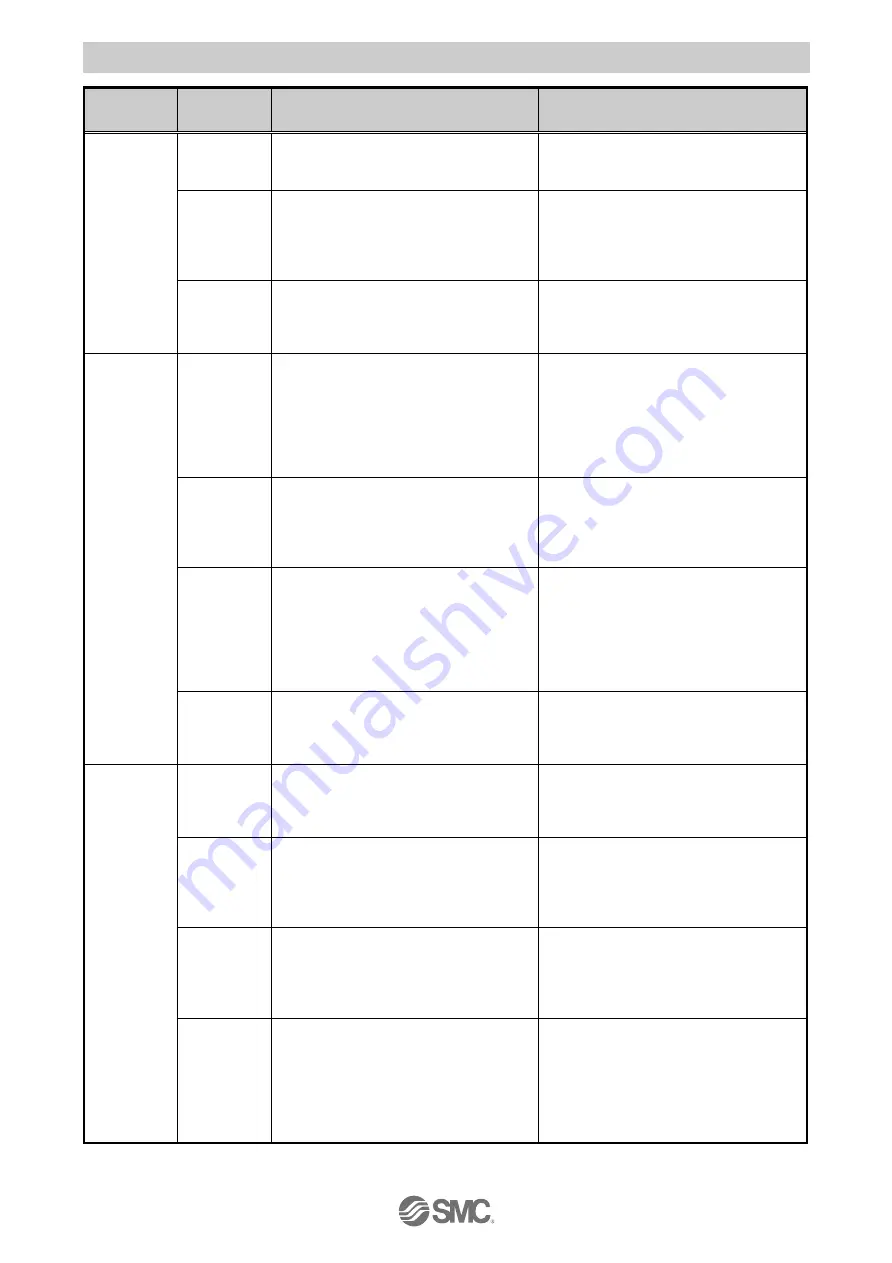

17.2 Position / Speed problems

Problems

Possible

causes

Investigation method

Countermeasures

The actuator

does not

move to the

correct

position.

Incorrect

origin

position

For a pushing operation, repeat the Return to

origin operation several times to check that

the actuator returns to the origin correctly.

Check the actuator operation (if foreign

matter is caught in the product etc.).

Incorrect

parameters

Check that the controller parameters are

appropriate and the program is correct.

Review the maximum speed, the

maximum acceleration and maximum

deceleration of the actuator.

Modify the parameters and test the

operation.

-> 9. Settings Data Entry

Unsuitable

specification

Check that the controller parameter

settings for the product model and power

supply specification are appropriate for the

actuator connected.

Check that the controller parameters for the

product number matches with the actuators.

Check that the power specification is correct.

-> 4. Product Specifications

The actuator

does not

move

correctly.

Incorrect

wiring

Check that the wiring is connected

correctly?

Refer to this operation manual to confirm

wiring, and check for broken wires and

short-circuits.

Correct the wiring so that the input/ output

of each signal is performed appropriately.

Prepare a separate power supply for the

main control, motor drive and motor

control, and input/ output signals.

-> 2.3 Product configuration

-> 6. Power supply connector

Unsuitable

specification

Check that the controller parameter

settings for the product modelandpower

supply specification are appropriatefor

the actuator connected.

Check that the controller parameters for

the product number matches with the

actuators. Check that the power

specification is correct.

-> 4. Product Specifications

Signal timing

Check the timing of the signal from the

PLC to the controller.

Leave an interval of 15ms or more

(recommendation is 30 ms) between

signals and maintain the state of the signal

for 15ms or more (recommendation is 30

ms), because PLC processing delays and

controller scanning delays can occur.

->10.7 PLC output signal response time

Data not

stored

correctly

Check that the data (step data, parameters)

is stored correctly. Do not turn off the

controller power supply or remove the USB

cable while data is being stored.

Input the correct data (step data,

parameters) again and confirm operation.

-> 4.2 Parts Description

-> 9. Settings Data Entry

Required

speed is not

achieved

Incorrect

parameters

Check that the parameter values are correct.

Review the maximum speed and the

maximum acceleration and deceleration of

the actuator.

Correct the parameter values and test the

operation.

-> 9. Settings Data Entry

Operation

pattern is not

suitable.

Check if a triangular acceleration /

deceleration is programmed for the actuator

operation. In case of such operation, the

actuator may start slowing down before it

reaches the maximum speed.

Modify the setting to make the movement

distance longer or the acceleration higher.

-> 9. Settings Data Entry

Unsuitable

specification

Check that the controller parameter

settings for the product model and power

supply specification are appropriate for the

actuator connected.

Check that the controller parameters for the

product number of the actuator matches

the actuator connected. Check that the

power supply specification is correct.

-> 4. Product Specifications

Voltage drop

Check for a temporary voltage drop in the

power supply? (If there is a temporary

voltage drop in the power supply, the EMG

terminal of the motor control power

connector will turn OFF, so the actuator will

stop. However, this stop will be released

when the voltage recovers).

There is a possibility of a momentary

voltage drop because the capacity of the

power supply is insufficient, or if the power

supply is an “inrush-current protection”

type.

-> 4. Product Specifications