No.

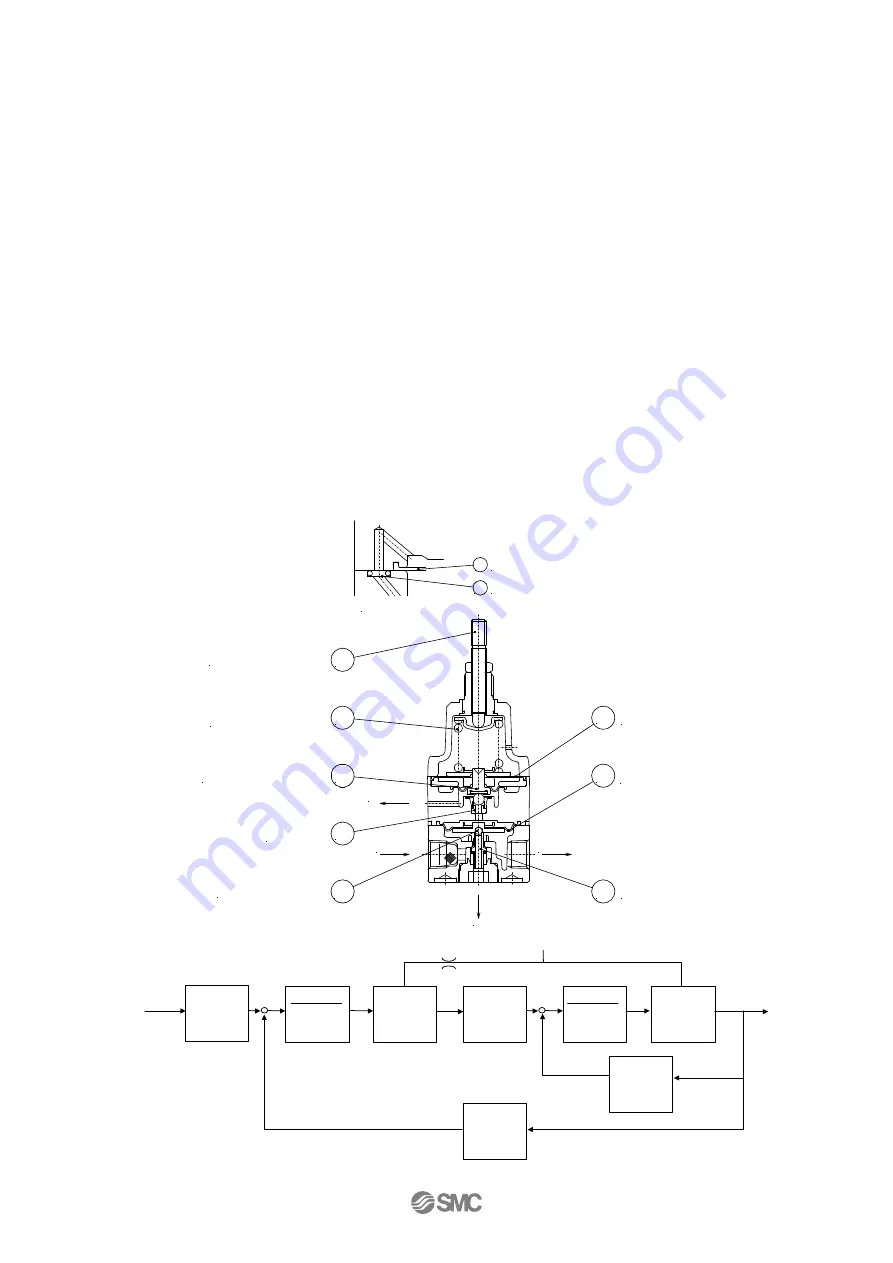

2. Structure and operating principles

When the Adjusting screw

①

is turned, the nozzle

③

is closed by the diaphragm disk

②

, allowing the

supply air that flows in from the upstream side to pass through the fixed orifice

④

and to acts on

diaphragm C

⑥

as nozzle back pressure, the main valve

⑦

is pushed down by the generated force and

the supply pressure flows out to the downstream side. The air pressure that flows in acts on bottom side

of diaphragm C

⑥

and while opposing the force generated by nozzle back pressure, it also acts on

diaphragm A

⑤

opposing the compression force of the setting spring

⑧

and balance with set pressure.

When the output pressure raises above the setting pressure, diaphragm A

⑤

is pushed up which makes

the interval between the diaphragm disk

②

and the nozzle

③

widens, the nozzle back pressure drops,

the pressure balance of upper/bottom part of diaphragms C

⑥

collapses. Then as the main valve

⑦

closes, the exhaust valve

⑨

opens at the same time and the excess pressure from the downstream side

is discharged to the atmosphere. In this way fine pressure variations are detected by the nozzle/flapper

type pilot mechanism, and precise pressure adjustment is performed. Deviation due to pressure

difference between in/outside of bourdon tube is transmitted to the sector through the rod to rotate the

pinion engaging the sector. The indicting needle and scale display the pressure value.

-5-

SUP

OUT

BLEED

E

X

H

5

6

7

9

3

2

8

1

Diaphragm A

Diaphragm C

Main valve

Exhaust valve

Nozzle

Diaphragm disk

Adjusting spring

Adjusting screw

4

Fixed orifice

6

Diaphragm C

SUP.side passage

Setting

spring

N/m

Diaph.C

m

2

Daiph.A

m

2

Nozzle

flapper

MPa/ m

Diaph.B

m

2

spring

Compd

.

1

(B)

m/N

Main valve

MPa/ m

(S)

Displ

m

+

Force

―

N

Displ

m

Press

MPa

+

Force

―

N

Displ

m

Press.

MPa

Force

N

Force

N

SUP

Fixed

orifice

spring

Compd

.

1

(A)

m/N