- 26 -

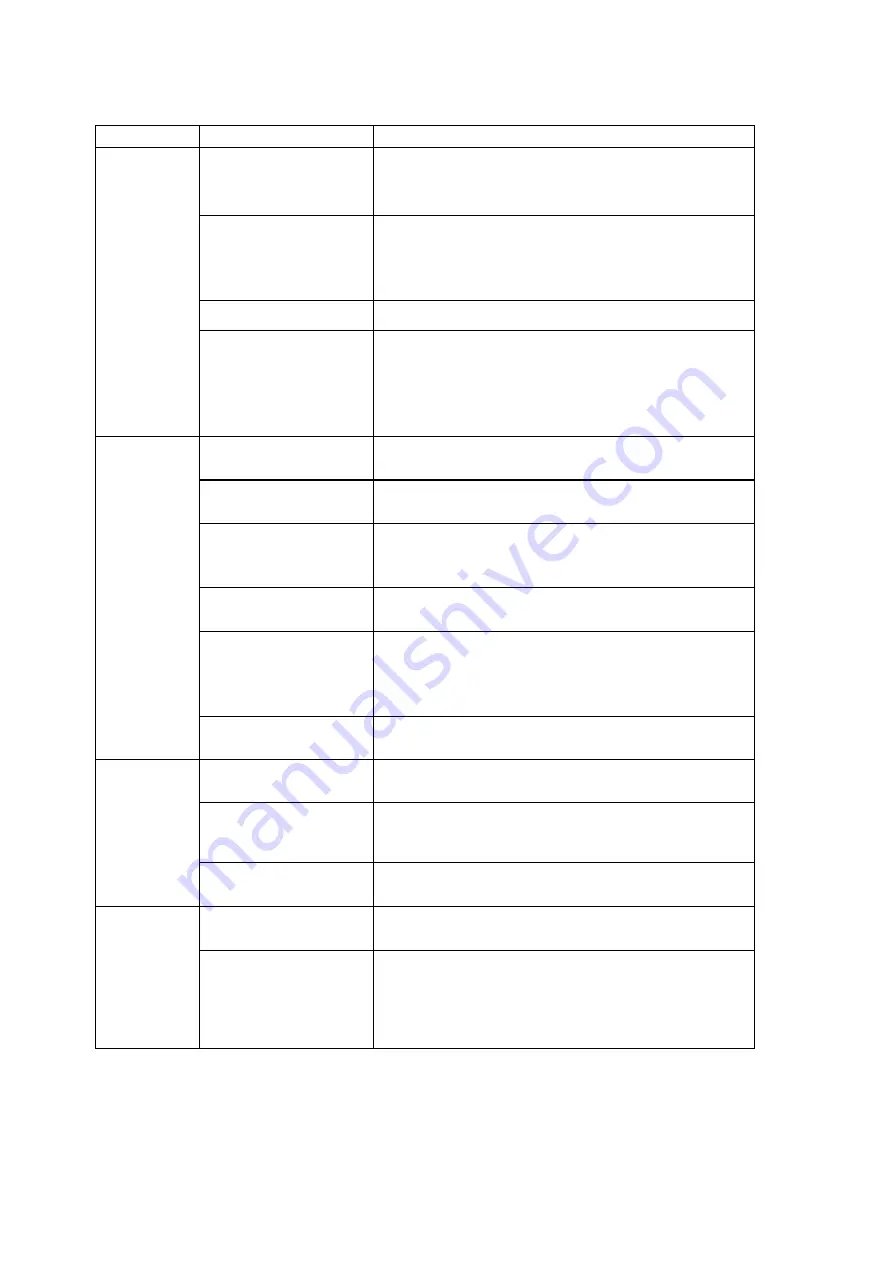

5. Troubleshooting

Table 12. Troubleshooting

Failure Main

cause

Action

1. Improper lubrication

●

Disassemble and apply applicable grease (lithium

soap group grease JIS #2 equivalent such as

“IDEMITSU DOUGHNY CORONEX GREASE #2”)

2. Rod deformation

●

Rod deformation is caused by offset load, side load,

over load, abnormal displacement of mounting

position, etc. Replace the piston rod assembly and

correct the abnormal load, position, etc.

3. Insufficient air pressure

●

Supply appropriate pressure.

1. Operation

is not

smooth.

4. Too slow operation

●

Even slight changes in the external conditions may

affect the speed in low speed operation. In such

case, please consider using air hydro or hydro

checker.

●

Change the cylinder to one with a larger bore size.

1. Abrasion and

damage to piston seal

●

Replace the seal.

2. Reduction in air

pressure

●

Check the pressure and the capacity of the pressure

source.

3. Insufficient air flow

●

Resistance in the passage might have increased

due to deformation of air flow passage or foreign

matter in the air. Repair and clean it.

4. Improper mounting

position of cylinder

●

Mount the cylinder in the proper position.

5. Deformation of

cylinder moving part

●

Cylinder is deformed by abnormal load, which

increases sliding resistance. Overhaul should be

performed and the piston rod assembly should be

replaced.

2. Output is

decreasing.

6. Improper lubrication

●

Refer to “Operation is not smooth” above .

1. Speed controller is

not used.

●

Use a speed controller which is suitable for the

cylinder size.

2. Lack of fine

adjustment of the

speed controller

●

Select a speed controller adequate to secure the

required operating speed by referring to the flow

characteristics curves.

3. Piston

operates too

fast.

3. Meter-in speed

controller is used.

●

To obtain stable speed even if load fluctuates, use a

meter-out speed controller.

1. Directional control

valve size is too small.

●

Use larger valve.

4. Piston

operates too

slowly.

2. Piping resistance is

too large.

●

Use appropriate size valve and other equipment.

Pay careful attention to the size of piping material

and fitting.

●

Use appropriate size equipment and piping on the

exhaust side.