- 23 -

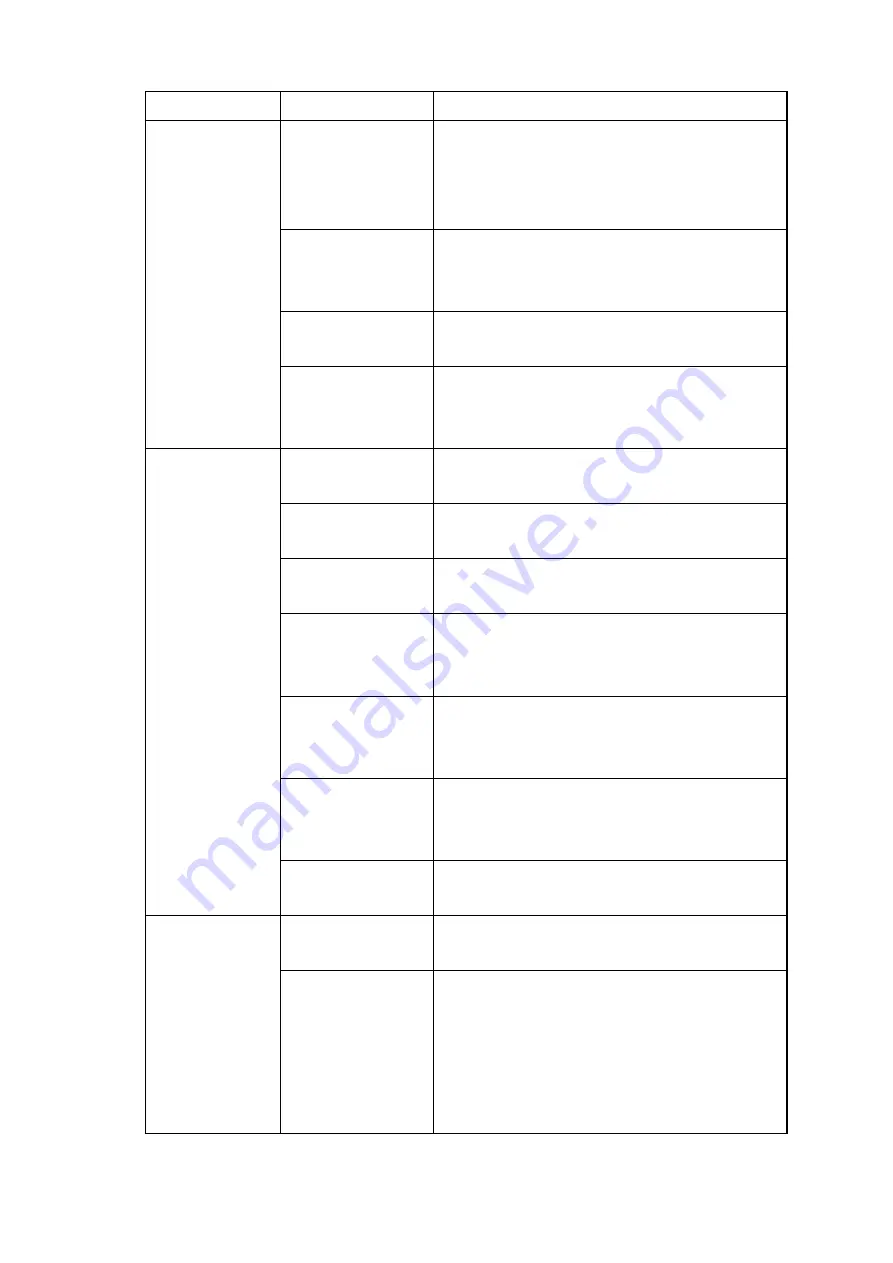

6. Troubleshooting

Trouble

Major causes

Countermeasures

Operation has

lost smoothness.

1. Shortage of

grease at the

sliding part of the

piston rod

- Apply the specified grease.

GR-S-010(10g),GR-S-020(20g)

2. Deformation of

piston rod

- Replace the cylinder with a new one.

When reinstalling the product, adjust the load and

mounting position.

3. Insufficient

pressure

- Supply appropriate pressure.

4. Operation at a low

speed outside of

the limit.

- Consult SMC.

Force has

decreased.

1. Air leakage from

piston seal

- Replace the cylinder with a new one.

2. Air leakage from

rod seal

- Replace the rod seal with a new one.

3. Decreased

pressure

- Secure sufficient pressure and review margin of

air supply source.

4. Insufficient flow

rate

- The resistance in the fluid path may have

increased due to deformation or foreign matter

entering the product. Perform repair or cleaning.

5. Incorrect

mounting position

of the product

- Mount in a proper position without any force

applied to the product.

6. Deformation of

piston rod

- Replace the cylinder with a new one.

When reinstalling the product, adjust the load and

mounting position.

7. Lubrication failure - Refer to the countermeasure for the trouble

“Operation has lost smoothness.”

Piston speed is

too fast.

1. Lack of speed

controller

- Use a speed controller suitable for the size of the

product.

2. Insufficient fine

adjustment of the

speed controller

- Select an adjustable speed controller to obtain the

required piston speed referring to the flow-rate

characteristics curve.