- 24 -

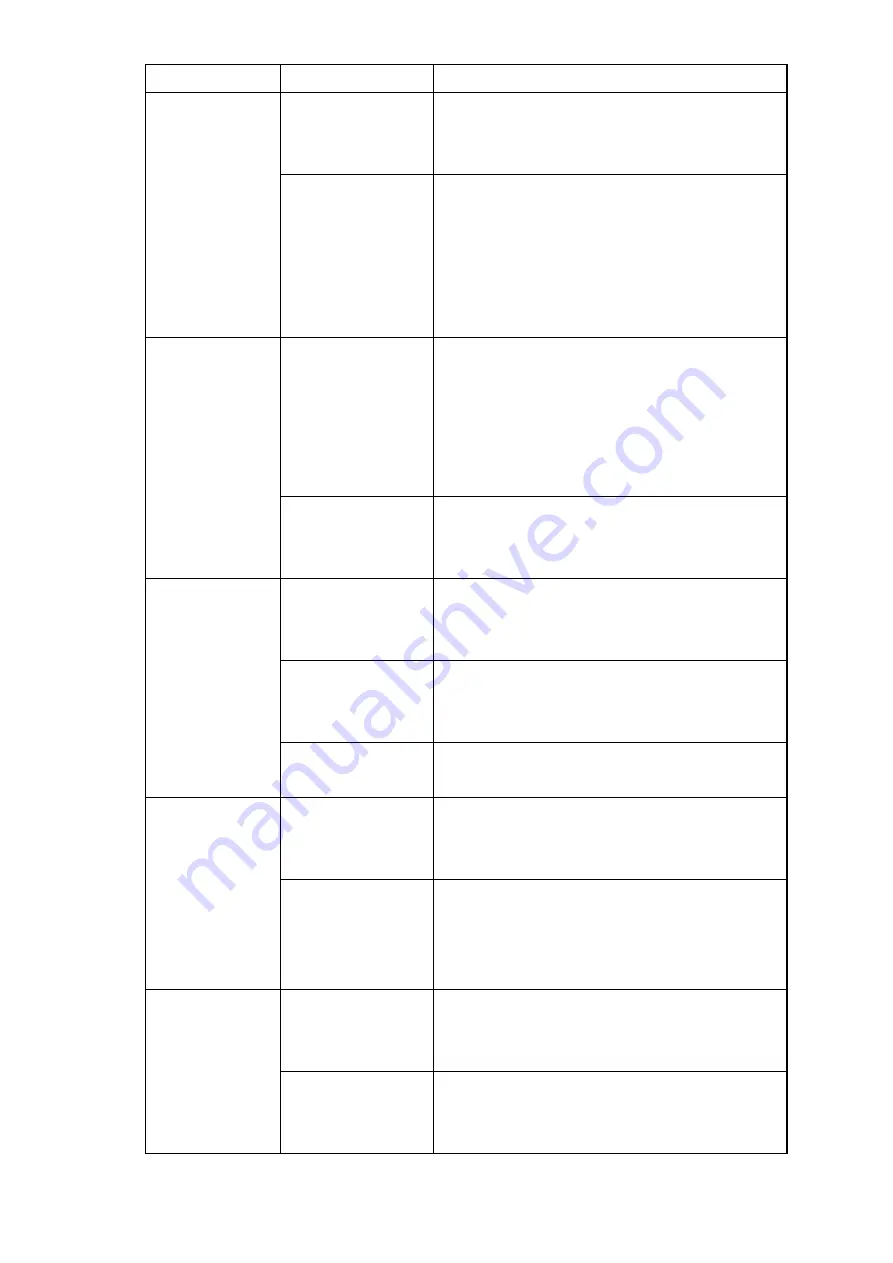

Trouble

Major causes

Countermeasures

Piston speed is

too slow.

1. Too small

directional

control valve.

- Use a valve of a larger size.

2. Too large

resistance of

equipment used

on the way of

piping

- Use valves and equipment of an appropriate size

- In particular, attention should be paid to the piping

and fittings because they are often missed.

Equipment and piping at the exhaust side should

also be of an appropriate size.

The product

sometimes does

not operate.

1. Operation at a

very low speed

-

Operation at a very low speed can create a

condition with almost no pressure difference

between the supply side and exhaust side and

lower sealing effect, which can cause operation

failure. Keep the specified speed for operation.

2. Problem of

equipment other

than this product

- Check all items in the system one by one to find

the cause.

The product has

become unable to

operate.

1. Damage of piston

seal

- Check that the exhaust port of the valve is

exhausting all the time. - Replace the cylinder with

a new one.

2. Problem of

equipment other

than this product

- Check all items in the system one by one to find

the cause.

3. Insufficient

pressure

- Supply appropriate pressure.

The piston rod

has been

deformed and

broken.

1. Operation at high

speed

- Operation at a high speed can cause impact, and

deform and damage the product. Keep within the

specified piston speed range.

2. Excessive

external force

- It may cause damage and deformation of the

cylinder if the mechanism interferes or eccentric

load or over load is applied to it. Remove these

factors.

Piston speed

cannot be

adjusted with the

speed controller.

1. Incorrect speed

controller

selection

- Use a speed controller of a suitable size for the

required speed.

2. Problem of the

speed controller.

- Replace the speed controller with a new one.