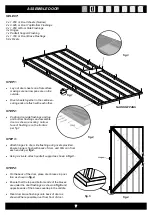

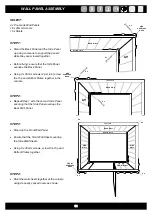

ASSEMBLE FRONT PANEL

10

BOTTOM PLATE

1854mm

1854mm

TOP PLATE

SELECT:

3 x 1.890 Wall Sheets

1 x 2.520 Top Plate (Red)

1 x 2.520 Bottom Plate (Green)

2 x 1.890 Door Jamb Flashings

40 x 30mm Galv Clouts

19 x Rivets

STEP 1:

•

Lay out 1 x Top Plate and 1 x Bottom Plate on a flat

surface as shown

STEP 2:

•

Using 2 x 30mm clouts, nail the Door Jamb Flashing flush with

the top of the Top Plate at the correct measurement as shown

in plan view. Pre drill holes using a 3.5mm drill bit

•

Check the distance between the top and bottom plates then use

a further 2 x 30mm clouts to nail the Door Jamb Flashings to

the bottom Plate. Pre drill holes.

STEP 4:

•

Place the door on the panel (In open position, approx

20mm below top of top plate). Using two rivets, rivet the top

and bottom hinges to the Door Jamb Flashing, ensuring

door closes properly.

•

Fit remaining rivets.

STEP 3:

•

Place 3 x Wall Sheets on timber, ensuring wall sheets fit un-

derneath door jamb flashings.

•

Ensure that the top of the sheets are flush with the top of the

Top Plate and that the sides of the wall sheets overhang the

Top Plate by

15mm

as shown. Nail wall sheets to Top Plate

(two clouts per pan)

•

Nail the wall sheets to the Bottom Plate making sure that the

Plates are the correct distance apart and that the sides of the

wall sheets overhang the Bottom Plate by

15mm

.

•

Drill & rivet Door Jamb Flashings to wall sheets using four

rivets equally spaced on each side.

NOTE:

The

Doorway is standard at 530mm from left

-

hand end.

To shift the doorway to the right

-

hand side of the front

wall, simply measure 530mm from the right

-

hand end.

NOTE:

Door can be hinged on either side.

IMPORTANT—IF YOU CHOOSE TO RAISE YOUR TIMBER

BASE PLATE –READ THE FOLLOWING;

For sheds with Raised Base Plate option only (see page 6), deduct

30mm from measurement shown between Top and Bottom Plates on

all wall panels, so cladding protrudes 20mm below bottom plate

.

TOP PLATE

TOP PLATE

15mm

15mm

15mm

15mm

530mm

960mm

TOP PLATE

DOOR OPENING

x3

x3

x3

Plan View

TOP

PLATE

DOOR

JAMB

NAIL

Summary of Contents for SM2525

Page 1: ...ASSEMBLY INSTRUCTIONS SM2525 BASE SIZE 2 520m x 2 520m ...

Page 2: ......