Page 4 of 18

Date: 2019-02-12

SKIPPER SB (Single Bottom) Sea Valve 100 mm

1. Installation

The SKIPPER SB Sea Valve 100 mm is used for installation of:SKIPPER speed log sensors and Echo

sounder transducers fitted with adaptor for XB-100-XX .

Caution!

Be aware that the Sea Valve contains high precision parts and therefore proper

handling when mounting is essential for the final result.

When handling the Sea Valve, all lifting devices must be attached on the outside of the

valve. It is very important to not insert any chains, wire, rope or any other device into

the valve chamber. This to avoid damaging and any kind of pollution of the Sea Valve.

Caution must be taken when mounting seavalves that all parts are aligned correctly, and that the inside is

clean. DO NOT use liguid sealants, and DO NOT paint the inside of a valve.

The SKIPPER SB Sea Valve 100 mm is delivered partly assembled for transport. The parts necessary for

final assembly will be found packed in a box delivered with the Sea Valve. First of all, it must be decided

where the Sea Valve should be installed. Normally, this will be in the fore part of the ship, in the centerline,

or as close to the centerline as possible. Optimal system operation is achieved by fitting the transducer/

sensor as deep as possible on the hull.

• The active surface of the sensor must be installed with front face a maximum of +/-1 degree to the ships

horizontal plane. (Speed Logs).

• The active surface of the transducer must be installed with front face a maximum of +/-7 degree to the

ships horizontal plane. (Echo Sounder).

Do not mount transducers close to the bow thruster propeller outlets, or aft of other hull installations (outlets,

vents or other protruding details) who may create aeration or turbulence.

It is necessary to select a part of the hull that is submerged and free from turbulence and aeration under all

load and speed conditions, and to avoid positions where air is trapped in heavy weather.

If a flat, horizontal section is not available for transducer fitting, the shipyard must construct a suitable bed.

Welding seams in this area should be smoothed and rounded off, in order not to create turbulence or aeration

at speed.

Protect the active element of the transducer/sensors during transport and installation, and

do not paint the surface.

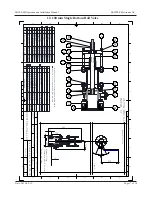

The Sea Valve should be placed in a service accessible place, large enough for installation and disassembly

of the sensor unit. See drawing: “Space considerations”.

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual