Cylinder Block

1---1

WORK INSTRUCTIONS

1. CYLINDER BLOCK

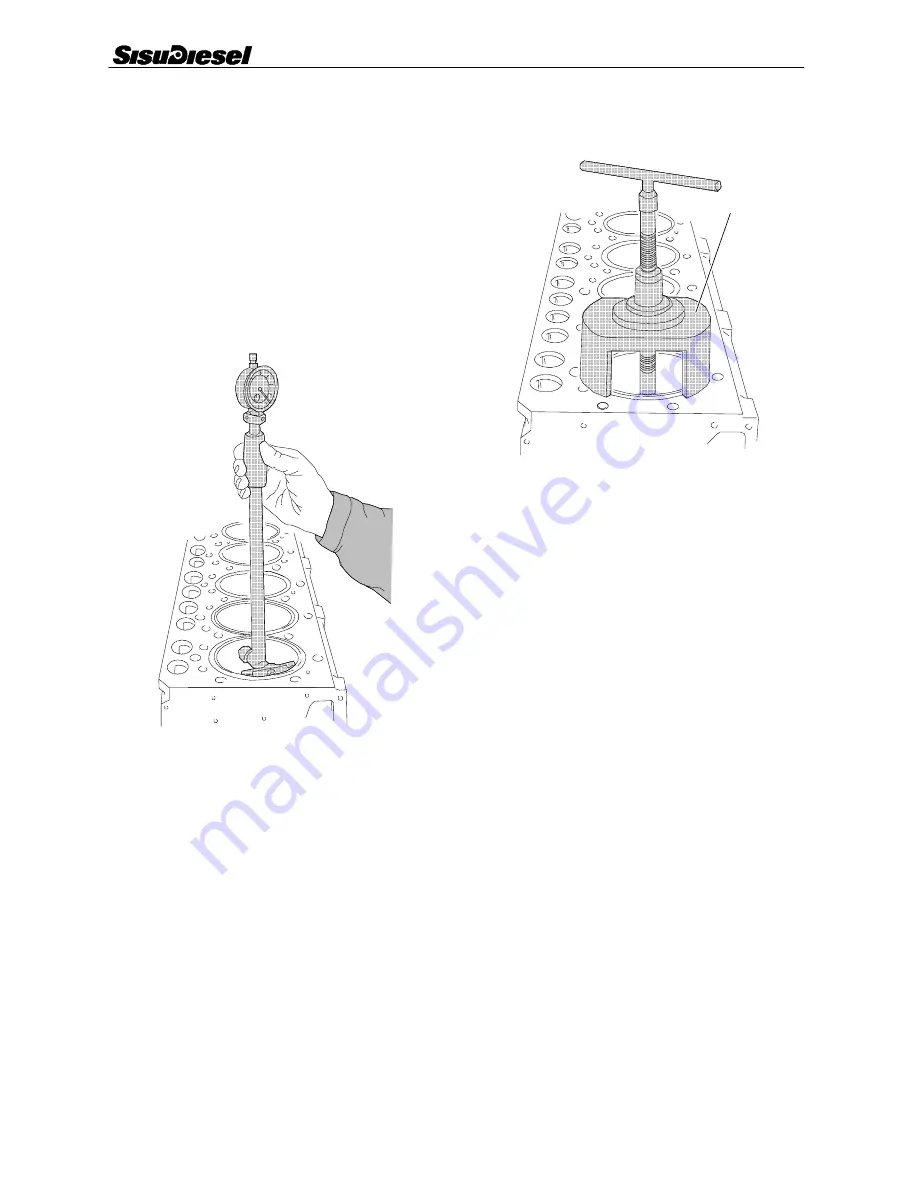

A. Measuring cylinder liner wear

1. Using a micrometer set the dial gauge to zero using a new

cylinder liner indicating the initial dimension of the bore:

111,00 mm.

2. Clean the inner surface of the cylinder liner thoroughly

before measurement.

41--- 1

3. Perform the measurement crosswise at the liner top end,

lower end and middle.

4. Check the gauge reading for maximum wear and ovalness

(compare with rated).

B. Removing cylinder liner

1. If the cylinder liners are to be used again they should be

marked so that they can be fitted in the same position.

9104 51500

41--- 2

2. Remove the cylinder liners using cylinder liner puller 9104

51500.

C. Checking cylinder block

1. Clean the cylinder block and all oil ways.

2. Check the cooling channels and remove the scale and

sediment to ensure engine cooling.

3. Check the tightness of the cup plugs and threaded plugs

in the cylinder block as well as the condition of the cylinder

block and sealing faces.

4. Measure the wear of the camshaft bearing points (com-

pare with rated).

Note!

If it is necessary to machine the upper face of the cylin-

der block, the pistons must be shortened by the same dimen-

sion. Observe the valve disc spaces on the piston upper face.

D. Changing camshaft bushing

On the 645---engines, all camshaft bearing points are pro-

vided with a separate bearing bushing.

1.Remove the camshaft rear end plug and tap the bushings

out with a long drift. Observe the different outer diameters

when removing.

2. Clean the bushings location carefully.