213--- 41

Fuel System

13---22

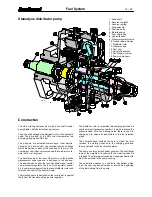

Stanadyne distributor pump

1. Drive shaft

2. Governor weights

3. Governor spring

4. Stop solenoid

5. Overflow valve

6. Metering valve

7. Cam ring rollers

8. Hydraulic head

9. Pressure regulator valve

10. Transfer pump blades

11. Distributor rotor

12. Pressure valve

13. Cam ring

14. Automatic advance

15. Centrifugal governor

16. Pumping plungers

Construction

The main rotating components are the drive shaft, transfer

pump blades, distributor rotor and governor.

The drive shaft engages the distributor rotor in the hydraulic

head. The drive end of the DB2 rotor incorporates two

pumping plungers and DB4 four.

The plungers are actuated toward each other simulta-

neously by an internal cam ring through rollers and shoes

which are carried in slots at the drive end of the rotor. The

numbers of cam lobes normally equals the number of cylin-

ders (not 3---cyl. engines).

The transfer pump at the rear of the rotor is of the positive

displacement vane type and is enclosed in the end cap.

The end cap also houses the fuel inlet strainer and transfer

pump pressure regulator. The face of the regulator assem-

bly is compressed against the liner and distributor rotor and

forms an end seal for the transfer pump.

The injection pump is designed so that end thrust is against

the face of the transfer pump pressure regulator.

The distributor rotor incorporates two charging ports and a

single axial port (pressure chamber), in which is placed the

pressure valve. After the delivery valve, there is one dis-

charge port to serve all head outlets to the fuel injection

pipes.

The hydraulic head contains the bore in which the rotor

revolves, the metering valve bore, the charging ports and

the connections to the fuel injection pipes.

The pump contains a mechanical governor. The centrifugal

force of the weights is transferred to the metering valve via

a linkage. The metering valve can be closed electrically with

aid of the solenoid in the pump housing.

The automatic advance is a hydraulic mechanism which

turns the cam ring and advances or retards the beginning

of the fuel delivery from the pump.