Cooling System

11---2

9104 27700

211--- 5

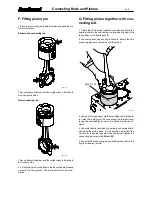

5. Remove the impeller using puller 9104 27700. Press the

shaft out of the pump body in the direction of the fan. Use a

hydraulic press. Support the body so that the shaft bearing

unit has enough space for releasing.

6. Tap out the axial seal in the body using a suitable drift.

Clean all parts and inspect their condition. Replace damaged

parts with new ones.

Note!

If the pump shaft has to be changed, use a recondition-

ing kit. This kit also contains all seals (see Parts Catalogue).

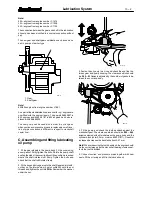

7. Press the shaft into its location in the body using special tool

9051 64900 and fit the circlip.

9051

79300

9051

40200

8353 39425

8353 31202

211--- 6

8. Fit the axial seal. Use as a ”lubricating liquid” coolant be-

tween the shaft and the seal. Two different seal types are

used. Both these seals are fitted with their own drift (see figure

above).

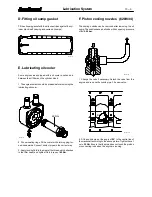

1,8...2,2 mm

178,5 mm

320

174,5 mm

320 E 7536>

420 E 7055>

211--- 7

420

9. Press the impeller and the hub to the correct depth (see fig-

ure) and support the shaft at the other end. Ensure that the

shaft can rotate freely. Fit the rear plate using a new gasket.

C. Reconditioning coolant pump

(Separate ball bearings 320, 420, 620, 634)

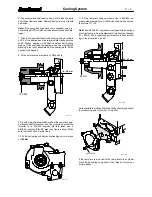

1. Drain the coolant. Remove the thermostat housing, fan and

the v---belt.

2. Remove the coolant pump. Detach the pump rear plate and

clean the sealing surfaces.

3. Unscrew the belt pulley fixing nut and remove the belt

pulley. Use puller 9052 48900 if needed.

9101 93200

211--- 8

9104 27700

4. Remove the impeller on the shaft with puller 9104 27700

(320/420---engines) or 9101 93200 (620/634---engines).

5. Remove the circlip in the pump body. Press the shaft to-

gether with bearings in the direction of the fan. Use e.g. a hy-

draulic press. Support the pump body so that the bearings

have enough space for releasing.