20--- 13

20--- 13/1

Construction

0---19

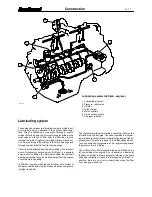

Inlet and exhaust system

The filter system for the engine inlet air comprises a cyclone

type precleaner, and a paper filter which acts as the main filter.

The incoming air is made to rotate in the cyclone precleaner.

This causes most of the impurities to settle out and collect in

the cyclone precleaner dust collector. The paper filter com-

prises one or two replaceable filter elements. The paper is

corrugated and surrounded by a metal support.

The impurities in the air collect at the larger filter element

which can be cleaned when necessary. The inner safety filter

prevents impurities form entering the engine should the main

filter element break, or be fitted incorrectly.

A mechanical or electrical service indicator can be mounted

on the filter housing or on the inlet pipe to show when the filter

cartridge is clogged. The inlet system also includes the hoses

between the air cleaner and the turbocharger and the turbo-

charger and the intake manifold.

The exhaust manifold is attached to the cylinder head with

high tensile bolts without a separate gasket. Retightening of

the manifold bolts is unnecessary.

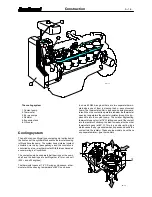

In the marine--- and generator engines a liquid cooled exhaust

manifold is used, that is connected to the engines cooling

liquid circulation (so---called freshwater circulation). These

exhaust manifolds are sealed from the liquid circulation part

with o---rings in 420---engines and with level seals in

320/620/634---engines.

The turbocharger is turbo---compressor driven by exhaust

gas. The compact design of the turbocharger is sensitive to

react even during low revolutions. The turbocharger is lubri-

cated and cooled by the lubrication system of the engine.

DW/DWI engine is equipped with a by---pass turbocharger

where the highest air pressure is adjusted by so---called by---

pass channel.

The compressed air is cooled by the air to water basis. The air

coming from the turbocharger has a temperature about

150

˚

C which is cooled by the cooling water of the engine

down to about 95

˚

C.

The cooling cell is installed on the intake manifold and con-

nected to the engine cooling system. The cooling of the com-

pressed air stabilised the combustion, irrespective of the tem-

perature, and minimises the thermal and mechanical load of

the engine thus lowering nitric oxides (NO

x

).