27

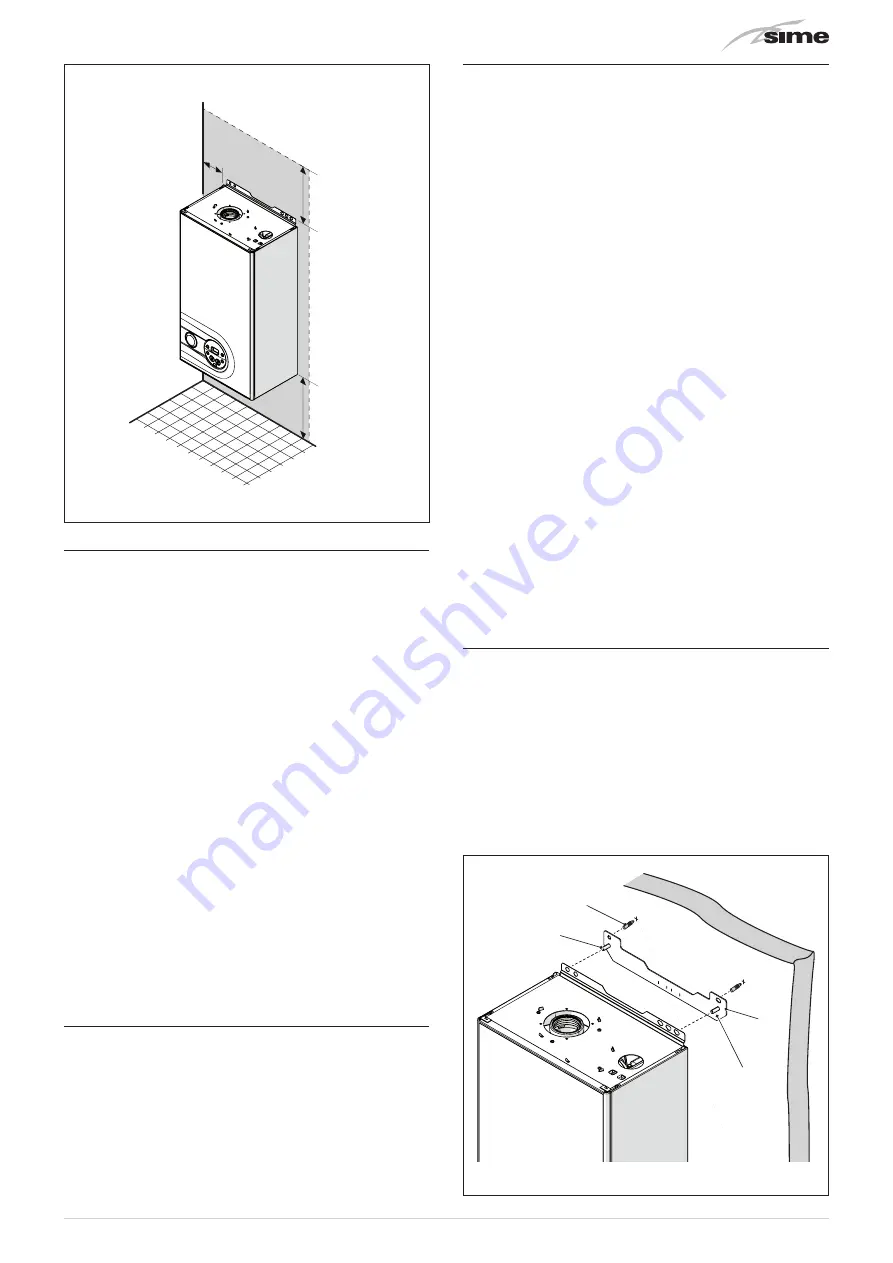

APPROXIMATE MINIMUM DISTANCES

≥ 15 mm

≥ 200 mm

≥ 200 mm

Fig. 17

6.5

New installation or installation of a re-

placement appliance

The boiler must be installed in a fixed location and only by spe-

cialized and qualified person in compliance with all instructions

contained in this manual.

The installation of this boiler must be in accordance with the

relevant requirements of the current Gas Safety (installation

and use), the local building regulations and I.E.E. wiring reg-

ulations.

Detailed recommendations for air supply and fluing are given

in BS5440.

The following notes are for general guidance: it is not neces-

sary to have a purpose provided air vent in the room or com-

partment in which the appliance is installed.

m

CAUTION

It is a condition of the warranty that the boiler is in-

stalled in accordance with the instructions in this

manual. The boiler must be registered with Gas Safe

Register, the Benchmark record must be completed

and the boiler is serviced annually and recorded in

this manual.

m

CAUTION

If the domestic water supply is metered or should a

water meter be added at a later time, a small expan-

sion vessel should be included in the domestic water

pipework.

6.6

Cleaning the system

Before connecting the boiler it is recommended that the system

be flushed in accordance to BS 7593, to eliminate any foreign

bodies that may be detrimental to the operating efficiency of

the appliance.

m

CAUTION

Failure to flush and add inhibiter to the system may

invalidate the warranty.

6.7

Characteristics of feedwater and system

treatment

– All recirculatory systems will be subject to corrosion unless

an appropriate water treatment is applied. This means that

the efficiency of the system will deteriorate as corrosion

sludge accumulates within the system, risking damage to

pump and valves, boiler noise and circulation problems.

– Before connecting the boiler the associated central heating

system must be flushed in accordance with the guidelines

given in BS 7593 “Treatment of water in domestic hot water

central heating systems”.

–

Sime Ltd

recommends only the use of FERNOX products for

the flushing and final treatment of the system water. This is

particularly important in hard water areas. Failure to flush

and add inhibitor to the system may invalidate the appliance

warranty. Artificially softened water must not be used to fill

the heating system. Naturally soft water areas can corrode

aluminium heat exchangers. Adding Fernox F1 or Mb-1 will

guard against corrosion.

–

Sime Ltd

promote the fitting of TF1 System filter with any new

boiler installation.

– It is important to check the inhibitor concentration after in-

stallation, system modification and annually on a service visit

in accordance with the manufacturer’s instructions. (Note

on benchmark service record this has been complete). Test

kits are available from inhibitor stockists; the return of the

Fernox test report should be kept with the Benchmark to val-

idate warranty.

– Where Central heating systems are susceptible to freezing

a mixture of inhibitor and anti-freeze should be added in ac-

cordance with the DWTA code of practice and the Manufac-

tures instructions.

– The addition of sealing agents to system water is not rec-

ommended because deposits can be left in heat exchanger

causing circulation issues.

6.8

Boiler installation

Murelle Pro HE MkII

are supplied with a hanging bracket and a

template to assist installation.

For installation:

– position the bracket (1) on the wall (2), where you want to

install the boiler

– check that it is straight and mark where to make the holes

for the plugs

– drill the holes and insert the expansion plugs (3) which will

be used to fix the bracket securely

– hook the boiler onto the pins (4) and secure it using the nuts

and washers supplied.

1

2

3

4

Fig. 18