13

20123476

GB

Installation

5.8

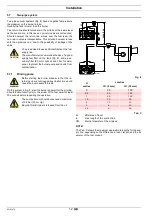

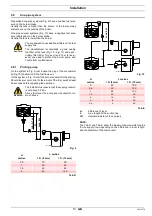

One-pipe system

Pressurised one-pipe systems (Fig. 9) have a positive fuel pres-

sure on the burner intake.

Usually the tank is higher than the burner, or the fuel pumping

systems are on the outside of the boiler.

One-pipe vacuum systems (Fig. 10) have a negative fuel pres-

sure (depression) on the burner intake.

Usually the tank is lower than the burner.

5.8.1

Priming pump

On the system in Fig. 9, just loosen the plug of the vacuometer

6)(Fig. 10) and wait until the fuel flows out.

On the system in Fig. 10, start the burner and wait for the priming.

Should lockout occur prior to the arrival of the fuel, await at least

20 seconds before repeating the operation.

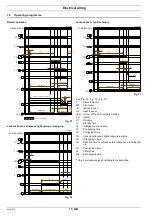

Tab. D

Tab. E

H

difference of level

L

max. length of the suction line

I.D.

internal diameter of the oil pipes

NOTE:

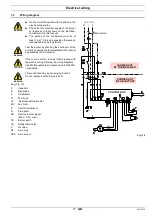

The Tab. D and Tab. E show the maximum approximate lengths

for the supply line, depending on the difference in level, length,

and the diameter of the fuel conduit.

CAUTION

You are advised to use additional filters on the fuel

supply line.

The manufacturer recommends a good quality

fuel filter at the tank (Fig. 10 - Fig. 11) and a sec-

ondary filter (60 m for gas oil and 15 m for kero-

sene) are used to protect the burner pump and

nozzle from contamination.

WARNING

The installer must ensure that the supply pressure

is not above 0.5 bar.

Above that level, the pump seal is subject to too

much stress.

H

metres

L metres

I.D. (8 mm)

I.D. (10 mm)

0.5

10

20

1

20

40

1.5

40

80

2

60

100

H

m

a

x

.

4

m

m

in

.

0

.1

m

D11009

Fig. 9

H

metres

L metres

I.D. (8 mm)

I.D. (10 mm)

0

35

100

0.5

30

100

1

25

100

1.5

20

90

2

15

70

3

8

30

3.5

6

20

H

m

a

x

.

4

m

D11010

H

Fig. 10