24

C = Every 2000 operating hours, or at least annually

W service intervals are to be performed by the customer.

In the run-in period - after approx. 100 service hours - or after repair work, the owner

must check the wheel nuts/bolts and re-tighten if necessary.

5.3.1Maintenance

5.3.1Maintenance

5.3.1Maintenance

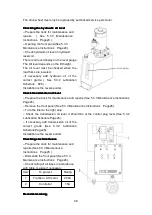

5.3.1Maintenance Checklist

Checklist

Checklist

Checklist

Standard

=

★

Cold Store

=

☆

W

A

B

C

Brake

1.1

Check magnetic brake air gap.

★

Electrics

2.1

Test instruments, displays and control

switches.

★

2.2

Test warning and safety device.

☆

★

2.3

Check fuse ratings.

★

2.4

Make sure wire connections are secure

and check for damage.

★

2.5

Test micro switch setting.

★

2.6

Check contactors and relays.

★

2.7

Frame leakage test

★

2.8

Test cable and motor attachments.

★

2.9

Check carbon brush wear, replace if

necessary.

★

Power

supply

3.1

Visually inspect battery

☆

★

3.2

Check battery cable connections are

secure, grease terminals if necessary.

☆

★

3.3

Check acid density, acid level and battery

voltage.

☆

★

Travel

4.1

Check motor suspension.

★

4.2

Check the transmission for noise and

leakage.

★

4.3

Replace gear oil if service life exceeded

(10,000 hours).

4.4

Check travel mechanism, adjust and

lubricate if necessary.

Check tiller recuperating function.

☆

★

4.5

Check wheels for wear and damage.

☆

★

4.6

Check wheel bearings and attachments.

★