MA47

Datum 16.06.2000

Art.Nr. 76671

Z.Nr. 8664049

Änd.Stand 201/00

1 1

Press key

to confirm and store the new

value.

If key

has not been pressed and no value has

been entered during approx. 30 seconds, the

display returns to display mode without making

any value correction.

Precondition: Menu point (rEF_F) in pro-

gramming mode must be programmed to "EIn" .

Offset value correction

Press key

(for at least 3 seconds) to activate

offset value input.

The display shows alternatingly the current refe-

rence value and the symbol „oFF“.

Use the arrow keys to enter a new value.

Press key

to confirm and store the new value.

If key

has not been pressed and no value has

been entered during approx. 30 seconds, MA47

returns automatically to display mode.

Precondition: Menu point (oFF_F) in pro-

gramming mode must be programmed to "EIn" .

Reset

Press key

to set the display to the program-

med reference / offset value.

Any programmed ‘incremental dimension’ (which

is signaled by the blinking comma) will be taken

into account.

8. Manual calibration

For setting the display to the reference / offset

value either

• press key

or

• briefly activate (by connecting to GND) input

RFS (terminal no. 6).

Precondition: Menu point_rFS_ in programming

mode must have been programmed to "Hand" .

The display can thus be zeroed, if the reference

value was previously programmed to 0.

9. Automatic calibration

Electronic linking of the signals from a reference

point transmitter (eg. cam switch or limit switch)

with the index pulse (index marker) of the con-

nected encoder will calibrate the measuring

display, ie. a start position is defined. During

mounting of the reference point transmitter,

please adjust the incremental encoder in such a

way that the index pulse only appears when the

reference point switch is activated.

The contact of the reference switch must only

e active for less than one revolution of the

encoder (see fig. 7).

Fig. 6 shows the mounting principle.

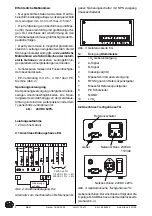

Fig. 6: Signal types for calibration

Fig. 7: Calibration setup

Information concerning the setting of the

reference point:

Move the spindle exactly to the position which

corresponds to the reference value programmed

as per chapter 8. The mecanically mounted

reference point transmitter must now be definite-

ly active (see fig. 5).

The encoder can be turned without causing any

movement of the driving spindle, if you untighten

the clamping ring or coupling. You can now

search the index signal of the encoder (voltage

change) by using for example a voltmeter and

carry out the adjustment to the reference point.

one turn

signal A

signal B

index-

signal

type O

type I

signal ref. point

transmitter

definitely

passive

definitely

active

definitely

passive

drive

driving spindle

ref. point

transmitter

increm.

encoder

incremental display MA07