Follow this by using a drum-sanding bit to smooth the edges and

contour the corner radiuses. Be careful to keep the edges as

smooth and uniform as possible, using the lines as a guide. Use

a sanding block with 220-grit paper to sand the straight edges

smooth. Finally, use a piece of 220 sandpaper to lightly sand all of

the edges, making them completely smooth.

Clean the cowl,

removing all dust and wipe off any remaining ink lines with alcohol.

The cowl should now be able to fit over the engine and onto the

front of the fuselage.

❑

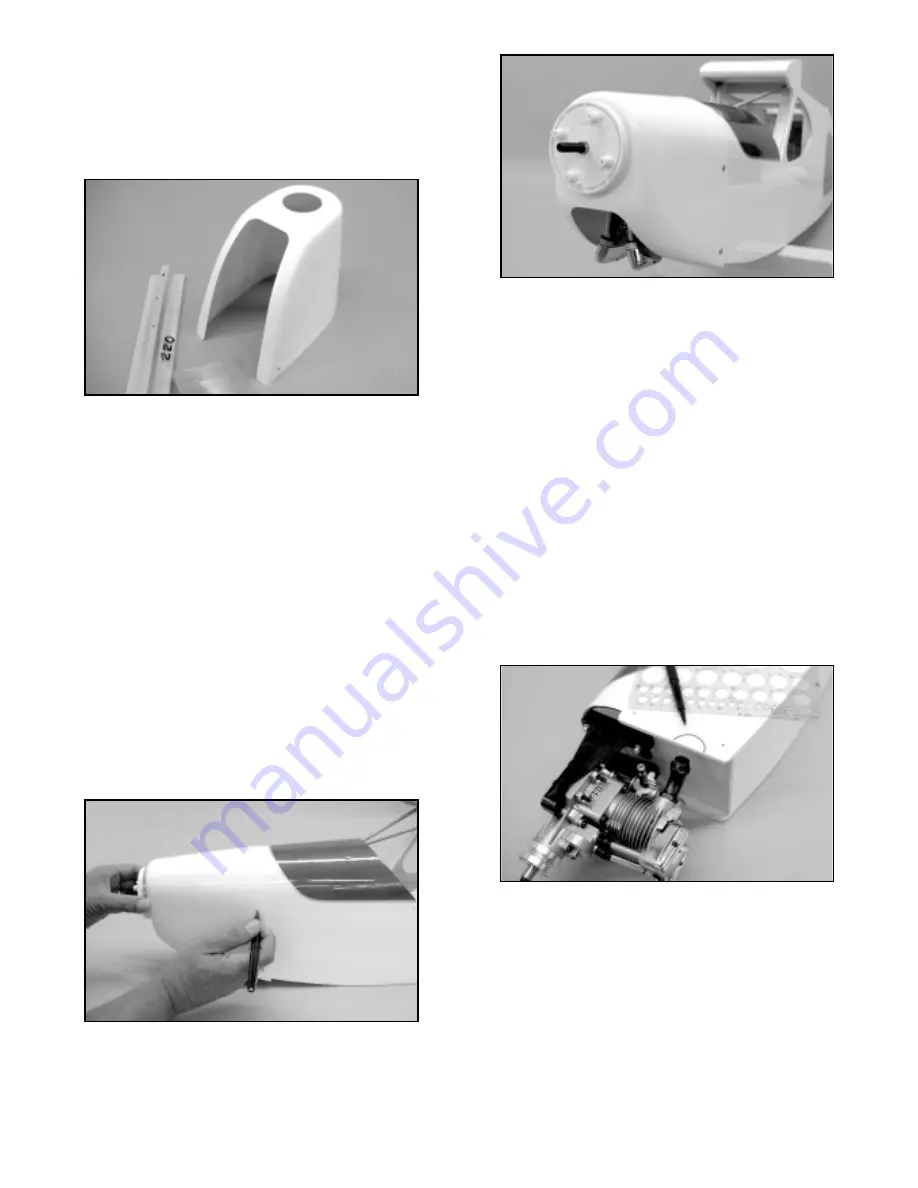

7) The cowl can now be mounted to the fuselage. To do this

as accurately as possible, it is helpful to have the spinner

backplate in position on the engine. From the kit contents, locate

the bag containing the Spinner Assembly. Remove the spinner

backplate and the four, molded shaft adapter rings from the

package. The center hole in backplate can be shimmed to fit many

engine prop shafts. However, our Saito 1.50 has a very large shaft

diameter - even larger than the hole in the backplate. This requires

that the hole be opened up with a drill to fit on the shaft. To do this

accurately, we used a drill press. Once the backplate fits onto the

engine, the cowl can be mounted.

Slide the cowl in place over the fuselage and then, place the

backplate onto the engine prop shaft. This gives you good visual

reference for centering the cowl to the spinner.

We suggest

leaving a gap of anywhere from 1/8" - 1/4" between the front of the

cowl and the backplate. Hold the cowl tightly in position and use a

non-permanent marker pen or pointed punch to mark the four

mounting hole locations on the fuselage sides, through the pre-

drilled holes in the cowl. Remove the cowl.

Use a 1/16" dia. bit to drill guide holes into the fuselage, about 1/4"

deep. Use the four #3 x 10mm PWA screws to mount the cowl to

the fuselage.

Do not over-tighten these screws at this time.

Remove the screws and the cowl, for now.

❑

8) The cowl is now prepared to clear the engine muffler. As

mentioned earlier, R/C engine muffler shapes and types are all

different and therefore, each engine/muffler installation tends to be

one of a kind. For example, our Saito 1.50 has a muffler manifold

shape and location that does not allow the muffler to exit the cowl

without interfering with the front of the fuselage. This fact means

that a small part of the front of the fuselage must be relieved to

allow muffler clearance. A flexible manifold tube and a Pitts-style

muffler may work to eliminate this issue but we chose to work with

the stock engine set-up. Here's how we did it.

With the engine in place on the mounts, lay the fuselage on its

side, manifold side up. Rotate the manifold on the engine head to

find the location on the fuselage that will require the least amount

of relief to allow the muffler to be mounted. In our case, this was

the lower, left side. Use a circle guide to determine the diameter

of the muffler (our Saito muffler measured just about 1-1/8" in

diameter). We used a non-permanent marker pen to mark the

fuselage with the approximate exit location for the muffler body,

using the next size up circle guide diameter - 1-1/4". This partial

circle mark becomes the guide for the initial relief of the fuselage

for muffler clearance.

Remove the engine from the motor mounts. Use a hobby knife and

#11 blade to cut away the covering material within the area to be

sanded. We used a scrap length of 1-1/4" dowel (aluminum tubing

or a scrap piece of pipe would also work just as well) and wrapped

it with 80 grit sandpaper. We, then, sanded the required channel,

at the same approximate angle that the muffler would sit on the

engine. Believe it or not, we sanded this relief channel perfectly

the first time! The channel was approximately 1/8" larger in

diameter than the muffler body, which is just about perfect for

clearance. Place the engine, with the manifold and muffler loosely

in place, back on the mounts to check your work.

Make any

adjustments needed to improve the channel. When it looks right,

remove the engine and lightly sand the finished channel with 220

sandpaper.

13