13

The firewall on the Edge 540T ARF has been factory-built with 2

O

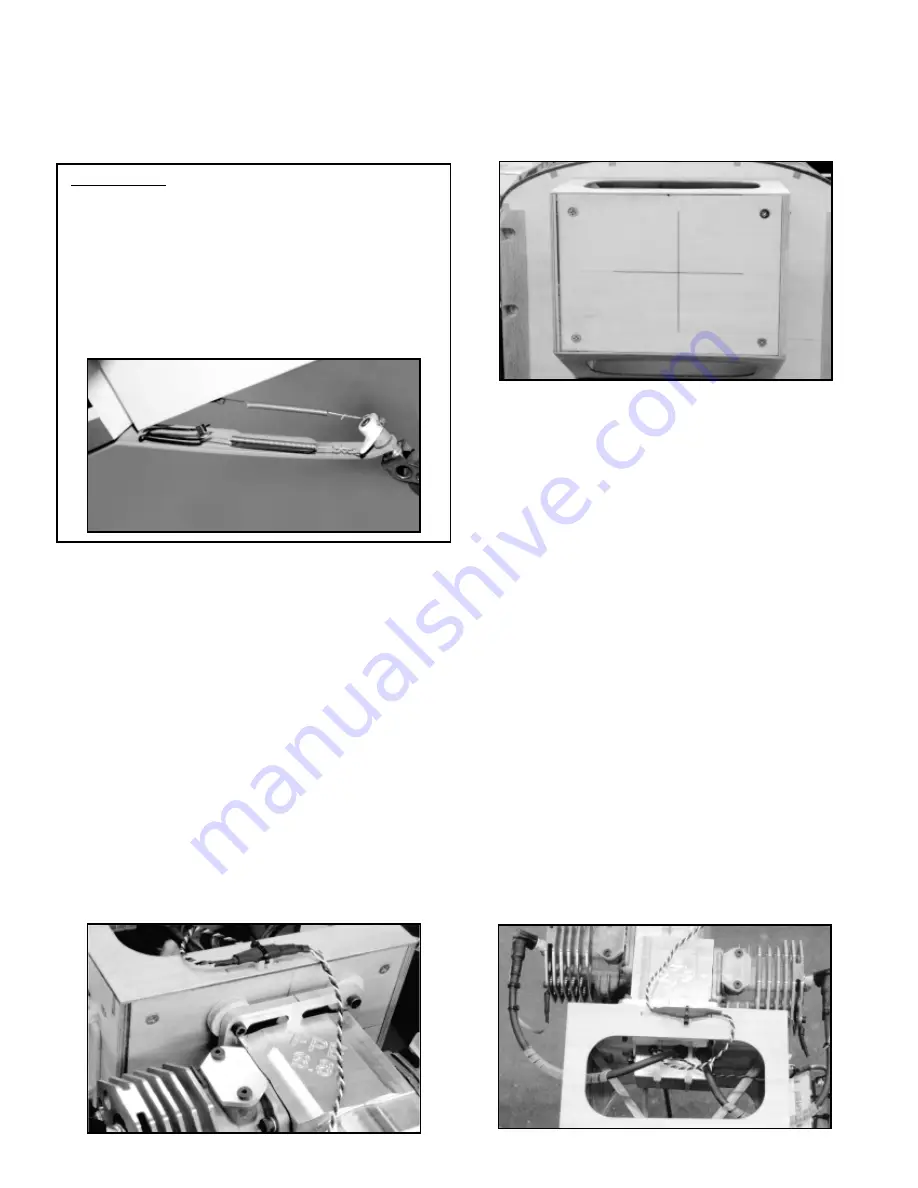

of right thrust. The firewall has also been accurately marked with

vertical and horizontal centerlines.

These two lines, at their

intersection, represent the centered position of the engine when it

is mounted to the firewall, taking into account the built-in 2

O

of right

thrust and the 7-7/32" distance to the cowl's spinner ring opening.

Using the vertical and horizontal centerlines, you can now

accurately measure the motor mount plate location against the

firewall and its bolt hole mounting locations. If required, you must

also now make the firewall mounting spacers for your particular

engine, to move it forward enough to clear the cowl by 1/8" to 3/16"

when the spinner backplate is in place on the engine.

When the mounting bolt hole locations have been accurately

marked on the face of the firewall, use an electric drill and the

appropriate bit to make the required clearance holes for the bolts.

As also mentioned earlier, you will need to provide your own

mounting hardware. We used four #10-32 x 1-1/2" hardened steel

hex head bolts with #10-32 lock nuts and flat washers to mount our

F.P.E. 6.8 engine. The engine and spacers can now be mounted in

place to the firewall. Check the cowl fit by sliding it in place over

the engine (with the mufflers removed) and onto the front of the

fuselage. Make any adjustments necessary.

Mounting The Ignition Module:

We mounted the electronic ignition module for our F.P.E. 6.8

engine to a simple lite-ply tray that was made from scrap 1/8" lite-

ply, sized for our specific module. We glued a couple of pieces of

1/4" sq. balsa on each end of the tray to keep the module from

shifting and then glued two more pieces of 1/4" sq. balsa to the

opposite side of the tray to stand it off from the back face of the

firewall. We cut a piece of 1/4" foam rubber to fit between the tray

and the module. The module was then secured to the tray with a

pair of cable ties.

We used epoxy glue to then glue the module tray to the back face

of the firewall, directly behind the engine.

In our F.P.E. 6.8

installation, this module mount location was perfect for routing the

shown, center the bracket onto the bottom of the rudder, with the

left and right arms spaced equally on each side.

Mark the

locations of the two mounting holes onto the rudder with a

marking pen. Use a .042" dia. bit (#58 index drill) to drill two screw

guide holes at the marks just made. Mount the bracket in place

with the two T2 x 12mm PWA screws.

Mounting The Engine:

As mentioned earlier in this manual, the distance between the

firewall and the outside surface of the cowl, at the spinner location

is 7-7/32". As also mentioned, this distance is adjustable aft about

1/8" or can be moved forward as much as a 1/2" or so. Therefore,

you need to now measure the length of the engine that you plan to

install in your Edge. The measurement you need is the overall

length of the engine, from the back surface of the mounting plate

forward to the back surface of the spinner backplate when it's in

place.

This measurement will tell you how far forward your

particular engine needs to be spaced from the firewall to fit within

the cowl, leaving about 1/8" - 3/16" clearance between the back

surface of the spinner backplate and the cowl itself.

For example, to mount our F.P.E. 6.8 twin cylinder engine in place

with the correct relationship to the firewall and the spinner

backplate, we needed to space it's mount 1/4" forward from the

firewall.

We did this by using 1/4" plywood to make four 1"

diameter disks. These four disks were then center-drilled with a

.193" dia. bit (#10 index drill) to provide clearance holes for the four

#10-32 mounting bolts. The photo shows the firewall, spacers, and

the bolts already in place.

MODELER’S TIP: The connection between the two centering springs

and the "T" bracket on the bottom of the rudder can be made using

two small cable ties. Doing this allows easy and accurate centering

of the tail wheel to the rudder and also avoids metal-to-metal contact

between the spring ends and the "T" bracket. The only requirement

needed to do this is to drill oversize holes in the "T" bracket arms to

allow clearance for the cable ties. We used a 7/64" drill bit to drill out

these two holes in the bracket.

The centering springs are each

attached to the tail wheel tiller arms as usual. The opposite ends of

each spring were bent with round-nose pliers to create a couple of

small loops in the wire. The connection between the springs and "T"

bracket arms were then made with 4" cable ties at each spring.