Summary of Contents for SITOP PSU100L 6EP1332-1LB00

Page 8: ...Safety instructions SITOP PSU100L 8 Manual 08 2016 C98130 A7603 A1 2 7629 ...

Page 20: ...Mounting removal SITOP PSU100L 20 Manual 08 2016 C98130 A7603 A1 2 7629 ...

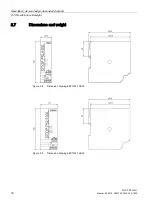

Page 42: ...Technical data 6 8 Dimension drawing SITOP PSU100L 42 Manual 08 2016 C98130 A7603 A1 2 7629 ...

Page 46: ...Safety approvals EMC 7 4 EMC SITOP PSU100L 46 Manual 08 2016 C98130 A7603 A1 2 7629 ...

Page 56: ...Environment SITOP PSU100L 56 Manual 08 2016 C98130 A7603 A1 2 7629 ...