Chapter 3 - Start-up Information

Wizards

23 | 180

Siemens Industry, Inc.

Siemens BT300 HVAC Drive

DPD01809

Building Technologies

2016-06-07

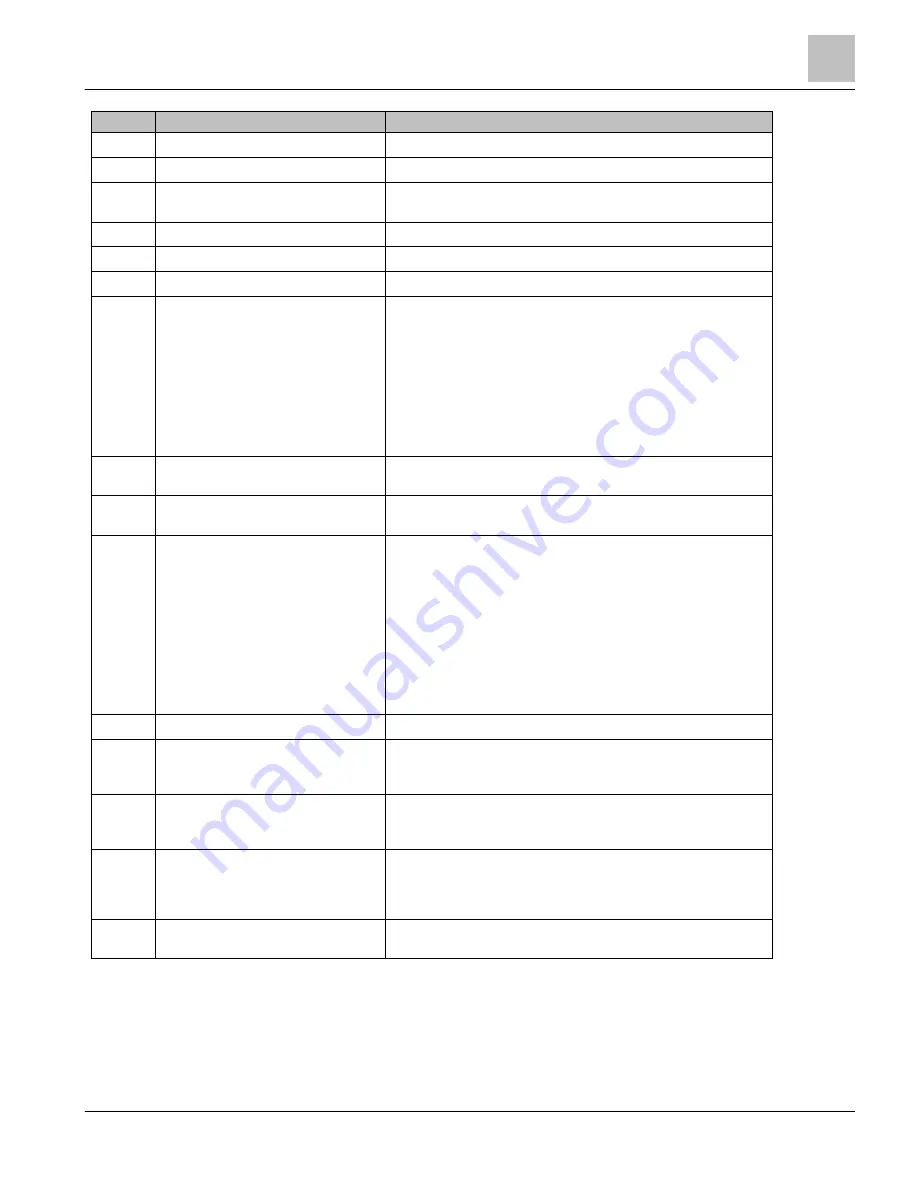

Step

Parameter/Question

Settings

10

Motor Nom Speed (P3.1.1.3)

Defines nominal motor speed from motor nameplate data.

11

Motor Nom Currnt (P3.1.1.4)

Defines nominal motor current from motor nameplate data.

12

Motor Cos Phi (P3.1.1.5)

(Power Factor)

Defines nominal motor Cos Phi (power factor) from motor nameplate

data.

13

Motor Nom Power (P3.1.1.6)

Defines nominal motor power from motor nameplate data.

14

Min Frequency (P3.3.1)

Minimum allowed frequency reference.

15

Max Frequency (P3.3.2)

Maximum allowed frequency reference.

16

I/O Ctrl Ref (P3.3.3)

Selects location of frequency setpoint source when in I/O A control. In

the following list of possible settings, the main setpoint is selected:

1= Preset Freq 0

2 = Keypad Reference

3 = Fieldbus

4 = AI1

5 = AI2

6 = AI1+AI2

7 = PID 1 Reference

8 = Motor Potentiometer

17

Accel Time (P3.4.2)

Defines the time required to increase output frequency from 0 to Max

Frequency (P3.3.1).

18

Decel Time (P3.4.3)

Defines the time required to decrease output frequency from Max

Frequency (P3.3.1) to 0 frequency.

19

Ctrl Place Auto (P3.2.1)

Start/Stop commands are given differently depending upon the control

place. This parameter defines whether the Start/Stop command is

controlled by digital inputs as defined in Control Signal 1 A (P3.5.1.1)

and Control Signal 2 A (P3.5.1.2) in accordance with the I/O A

Start/Stop Logic (P3.2.6) or if the Start/Stop command is controlled by

the Fieldbus that is in use.

Settings:

0 = I/O Control (control is from the physical I/O, PID control, or time

channels)

1 = Fieldbus (control is from the configured fieldbus found in Ethernet

or RS-485 settings).

20

Automatic Reset (P3.10.1)

Determines if the Automatic Reset feature can be used.

21

Start Function (P3.2.4)

Defines the start function of the drive.

0 = Ramping Start

1 = Flying Start

22

Stop Function (P3.2.5)

Defines the stop function of the drive.

0 = Coast to Stop

1 = Ramping Stop

23

Motor Switch (P3.1.2.2)

Prevents the drive from tripping when a motor switch is located

between the drive and motor.

0 = No

1 = Yes

24

Bypass Wizard (P1.21)

Enable parameter for the Bypass Wizard. This wizard can be activated

during the Startup Wizard.

The Startup Wizard is now complete.

Summary of Contents for BT300 LonWorks

Page 1: ...Siemens BT300 HVAC Drive Operator s Manual DPD01809 Building Technologies 2016 06 07 ...

Page 8: ......

Page 179: ......