Ordercode: 30690

Studio Beam CDM/HCI-150

Maintenance

The operator has to make sure that safety-related and machine-technical installations are to be

inspected by an expert after every year in the course of an acceptance test.

The operator has to make sure that safety-related and machine-technical installations are to be

inspected by a skilled person once a year.

The following points have to be considered during the inspection:

01)

All screws used for installing the device or parts of the device have to be tightly connected and

must not be corroded.

02)

There may not be any deformations on housings, fixations and installation spots.

03)

Mechanically moving parts like axles, eyes and others may not show any traces of wearing.

04)

The electric power supply cables must not show any damages or material fatigue.

The Studio Beam CDM/HCI-150 requires almost no maintenance. However, you should keep the unit

clean. Otherwise, the fixture’s light output will be significantly reduced. Disconnect the mains power

supply, and then wipe the cover with a damp cloth. Do not immerse in liquid. Wipe lens clean with glass

cleaner and a soft cloth. Do not use alcohol or solvents.

The front lens will require weekly cleaning, as smoke-fluid tends to build up residues, reducing the light-

output very quickly.

Please clean internal components once a year with a light brush and vacuum cleaner.

Make sure connections are thoroughly dry before supplying electric power.

Changing the lamp

01)

Disconnect mains power supply. Loosen the knurled bolt on the back of the device.

02)

Remove the rear cover.

03)

Follow directions for installing the lamp, page 9.

Replacing the Fuse

Power surges, short-circuit or inappropriate electrical power supply may cause a fuse to burn out. If the

fuse burns out, the product will not function whatsoever. If this happens,

follow the directions below to do

so.

01)

Unplug the unit from electric power source

.

02)

Insert a screwdriver into the slot in the fuse cover.

Turn the fuse holder counterclockwise.

The fuse will

come out

.

03)

Remove the used fuse. If brown or unclear, it is burned out

.

04)

Insert the replacement fuse into the holder where the old fuse was. Reinsert the fuse holder. Be sure

to

use a fuse of the same type and specification. See the product specification label for details.

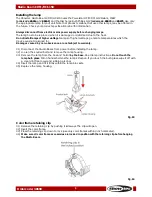

Cleaning VNSP, NSP, MFL and WFL glass lenses

01)

Place the fixture with the front facing you. Tilt the fixture slightly (fig. 07).

02)

Position the rotation ring with the spring at the top of the fixture, below the retaining clip.

03)

Hold the lens by the edge, so that the convex side faces the back side of the device (fig. 06).

04)

Dampen a clean lint-free cloth with vinegar or household ammonia. You may also use water, but it

will leave spots that can be removed by gently polishing the lens with a clean and dry cloth.

05)

Starting from the center, gently wipe the lens.

06)

Gently push the lens until it is positioned properly.

11