23

Maintenance and care

Keep dirt away from engine and air intake grid.

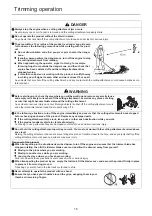

Cleaning silencer

Carbon deposits in silencer (A) will cause a drop in engine out-

put and overheating. Clean deposits from silencer.

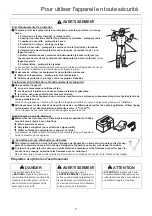

Check fuel system

Check before every use.

After refuelling, make sure fuel does not leak or exude from

around fuel pipe (A), fuel grommet (B) or fuel tank cap (C).

In case of fuel leakage or exudation, there is a danger of fire.

Stop using the machine immediately and request your dealer

to inspect or replace.

Check spark plug

1.

Check plug gap. Correct gap is 0.6 mm to 0.7 mm.

2.

Inspect electrode for wear.

3.

Inspect insulator for oil or other deposits.

4.

If the electrodes or terminals are worn, or if there are cracks

in the ceramics, replace them with new parts.

5.

Tighten to 15 N·m - 17 N·m (150kgf·cm to 170 kgf·cm).

The spark test (for checking whether the spark plug is spark-

ing) must be carried out by your dealer.

Lubricating flexible shaft

All the surface of the flexible shaft should always be properly

greased.

At the time of delivery from the plant, this is greased, so evenly

grease all the surface of the flexible shaft approximately 10 mL

in every 18 hours.

1.

Draw out the flexible shaft assembly from the angle trans-

mission.

Air intake

IMPORTANT

Do not remove the silencer cover. If necessary, Please consult

your dealer.

DPP

Summary of Contents for BP510S

Page 2: ...2 ...

Page 67: ...33 X750 026920 X750222 7601 2015 1Remarques et dos de couverture NOTES ...

Page 68: ...34 X750 026920 X750222 7601 2015 NOTES ...

Page 69: ...35 X750 026920 X750222 7601 2015 NOTES ...

Page 135: ...3 ...