- 10 -

Before Setting

Reminder 1

: The mark affixed to a value or a character on

each screen signifies that the setting is being

changed. When the

key is pressed to

register it, the mark goes out.

Reminder 2

: In the event no key is pressed for more than 3

minutes on any screen, the display automatically

returns to "0-0 basic screen."

Do not forget that if the basic screen returns

while a change in setting is going on, newly set

data will not have been registered.

Reminder 3

: When keylock is set and COM is selected as

communication mode, setting by key operation

is not possible.

Reminder 4

: External operating input is expressed as DI1,

DI2 and DI3 and event output as EV1, EV2 and

EV3.

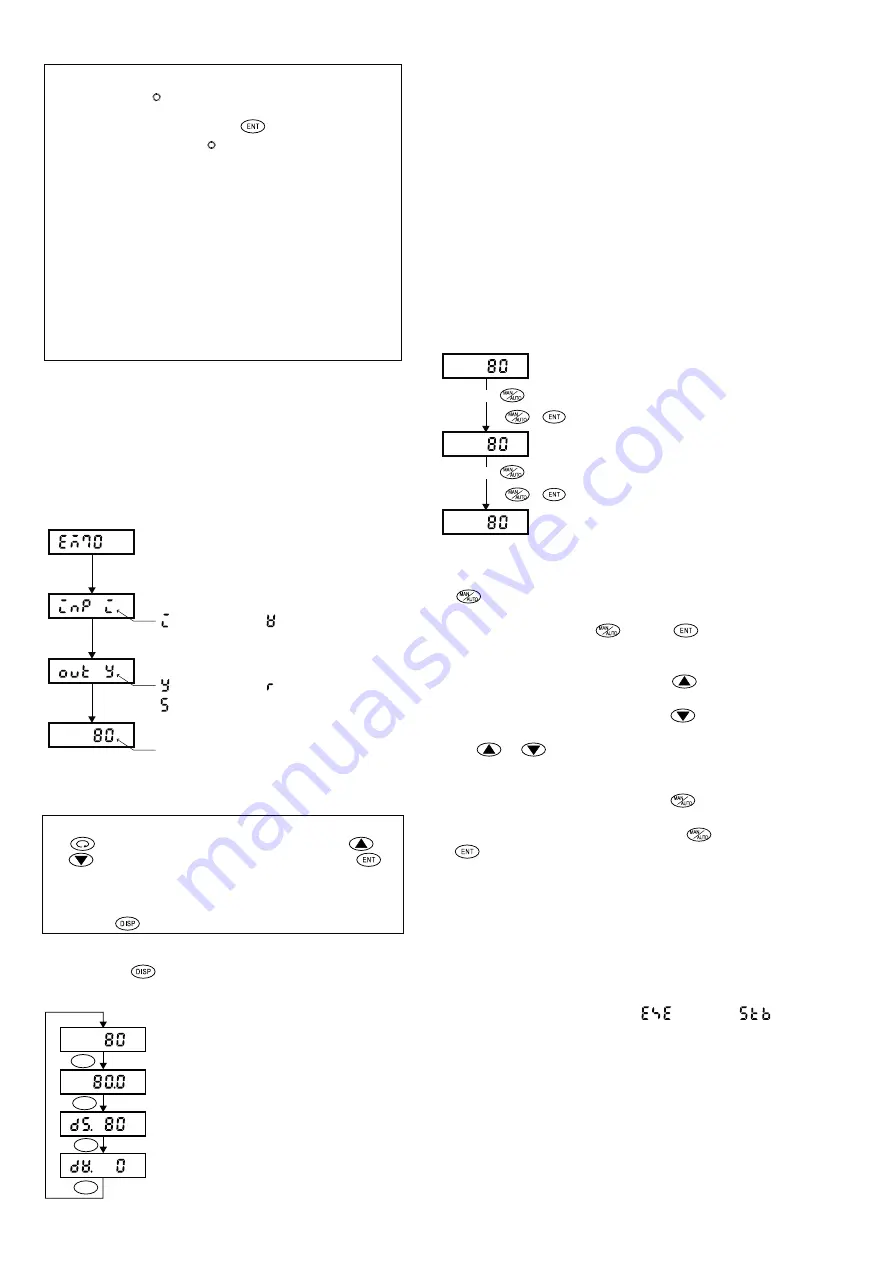

7-2. Display upon Power-ON

When power is applied, initial screens upon power-ON are

displayed successively, each for about 2 seconds to allow you to

see the types of input and output of this instrument. Then, in

about 2 seconds, the basic screen is displayed. From this screen,

the display proceeds to screens for setting various functions by

means of operating keys. For the order of screens to appear,

refer to 6-1 Parameter Flow.

Model display

2 sec.

2 sec.

2 sec.

Input type display

: Current input

: Voltage input

: Contact output

: Contact output

Output type display

0-0 basic screen

Present value of position, % is shown by

a numeral value.

7-3. Explanation of Screen Group 0 and Parameter Setting

Method of key operation

The

key is used to proceed to the next screen, the

and

keys for selection on each setting screen and the

key for registration. (For a change of data display, see the

following section.)On any of the screens in this screen group,

except the ones described in (1) Changing Data Display,

pressing the

key calls back the 0-0 basic screen.

(1) Changing Data Display

Pressing the

key on the 0-0 basic screen changes various

display values.

0-0 basic screen, position display

PO

SITION dis

play lamp lights.

0-0-1

i

nput value

0-0-2 target value of position

0-0-3 deviation value

I

NPUT

display lamp lights.

D

ES/DEV

display lamp lights.

D

ES/DEV

display lamp lights.

DISP

DISP

DISP

DISP

0-0 Basic screen:

Present position value is displayed in %.

0-0-1 Control input value display screen:

Control input is displayed in %.

0-0-2 Target position value display screen:

Target position value is displayed in %. In case higher and

lower limit limiters of position (See screen group 1.) are set,

however, it is limited by limiter values.

0-0-3 Deviation value display screen:

A value obtained by deducting target position value from

present position value is displayed. (Deviation value =

position value - target position value). Even when deviation

value exceeds -99%, -99% is displayed.

(2) Manual Operation

Manual operation (Manual/Auto and Open/Close are changed on

the 0-0 to 0-0-3 screens.)

0-0 basic screen

( + )

POSITION display lamp lights.

Manual operation mode

MAN display lamp flashes.

Automatic operation mode

MAN display lamp flashes.

Pressing key for 2 seconds.

Pressing key for 2 seconds.

( + )

Change from automatic operation to manual operation:

Automatic operation is changed to manual operation when

key is pressed for 2 seconds continuously on the basic

screen. The MAN display lamp flashes. (This can be done

alternatively by pressing

key and

key

simultaneously.)

Key operation during manual operation:

During manual operation, pressing the

key lights the

OPEN lamp and opening control output is produced.

During manual operation, pressing the

key lights the

CLOSE lamp and closing control output is produced. Press

the

or

key while watching the position display, and

the intended position can be set.

Releasing the manual mode:

During manual operation, pressing the

key for 2 seconds

releases manual operation. The MAN lamp goes out and

automatic operation begins. (Pressing the

key and the

key simultaneously is alternate means to switch to

Automatic operation.)

Note on manual operation:

During manual operation, the motor keeps operating at 100%

speed regardless of a set speed. You should be observant for

system information constantly during manual operation.

Special care is required if you leave the site while manual

operation is going on.

(3) Switch between Operation and Suspension

[0-1 operation screen: Iinitial value:

Operation,

Suspension]

Swich between Operation/Suspension is possible while

Automatic Operation.

: SSR output