16

MAINTENANCE SECTION - Continued

SPINDLE ASSEMBLY - Continued

5. Tap the square key into place in the upper

shaft. Wrap masking or electrical tape around the

shaft and key. This will keep the key in place and

will prevent the shaft from slipping out of the

housing during reassembly to the mower deck.

6. Reinstall the lube filling in the top of the shaft.

SPINDLE REINSTALLATION

1. Place the spindle into the deck from the

bottom and retain with 7/16 fine thread locknuts.

Torque all four nuts to 35-45 ft. lbs. (48-61 Nm).

2. Remove the tape from the spindle shaft and,

while holding the shaft from the bottom, install

the belt pulley, 3/4 flat washer and 3/4-16

locknut.

3. Install the spindle washer, mowing blade,

blade spacer and 9116-12 x 1-3/4 Grade 8 bolt.

See parts page 28 for item illustrations.

4. Torque the blade bolt, using a spanner wrench

through the holes in the pulley, to 110-130 ft. lbs.

(150-1 77 N Torque the pulley nut to 80 ft. lbs.

(109 N-m). Re-torque these fasteners after one

hour of mower operation and daily thereafter.

5. Lubricate the spindle with a high quality

multipurpose grease until the grease begins to

vent from around the UPPER seal.

IMPORTANT.

The rebuilt spindle should be greased again after

15 minutes of operation to ensure that air

pockets in the spindle housing have been fully

purged

6. Reinstall the mower deck to the tractor

RECONDITIONING THE DRIVELINE

DRIVELINE DISASSEMBLY

1. Disconnect the rear half of the driveline from

the tractor PTO shaft, slide it out of the front half

and lay it aside.

2. Loosen the two bolts that retain the driveline

shield to the mower gearbox and pivot it upward

out of the way.

3. Remove the fastener through the driveline

yoke, remove the snap ring from the gearbox

input shaft, and remove the front half of the

driveline from the mower.

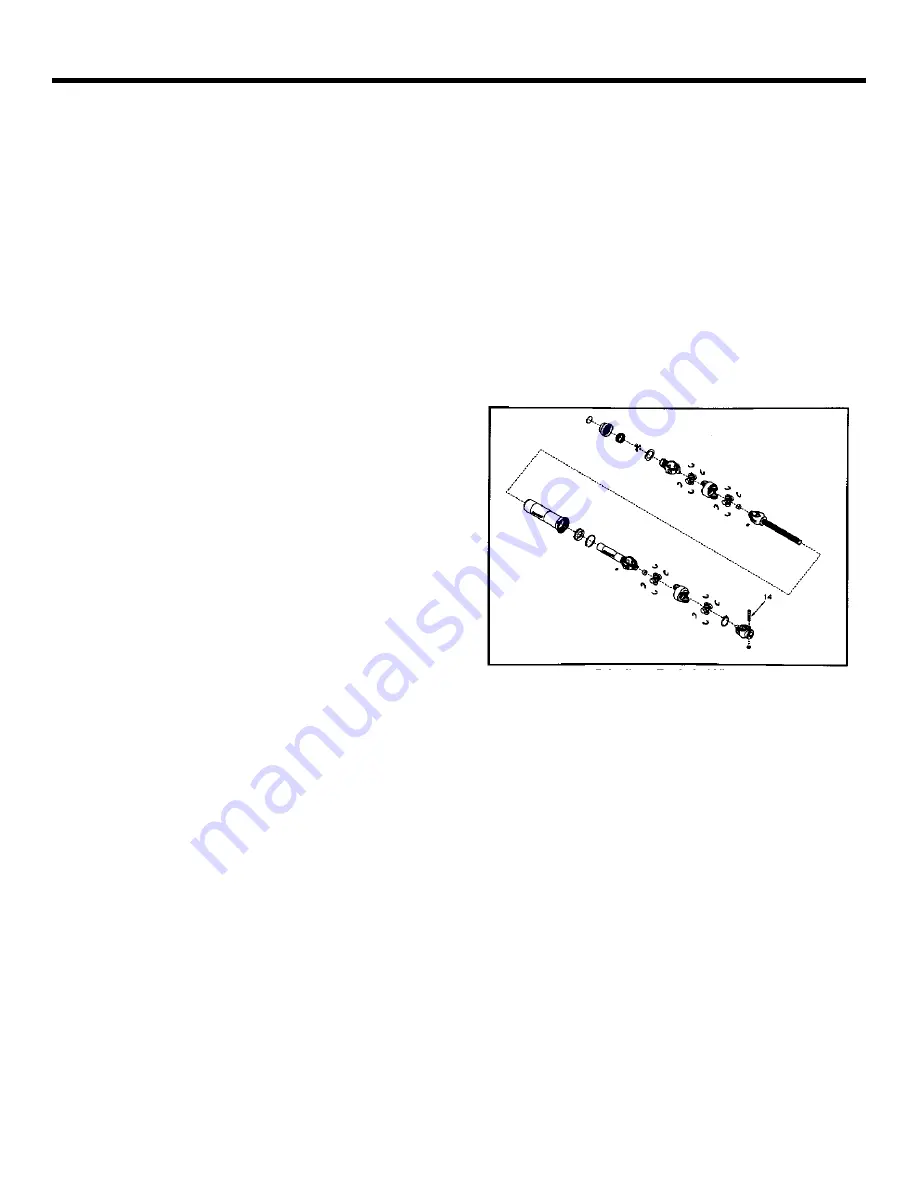

Driveline - Exploded View

4. Clamp the front half yoke securely in a belt

vise with jaws that are lined with wood board

brass or copper faces, etc. Remove the exterior

snap ring from inside the lock collar. Slide

collar and spring off of the yoke. THE BALLS

WILL FALL OUT! Use care so they a not lost.

5. Tear down the remaining driveline as

necessary. Lay the U-joints aside and wash all

other parts with clean solvent. Inspect and

replace the U-joint or any other item that is badly

worn or damaged