ENGLISH

GB-4

8 mm

8 mm

40 mm

50 mm

2

N

(1)

4 5

Lo

Hi

(3)

(2)

(1)

DETACHING THE UNIT FROM

THE MOUNTING PLATE

Push the “ “ marks at the bottom of the

indoor unit and pull the bottom of the unit.

When the hooks are released from the mount-

ing plate, support the bottom of the unit and

lift the unit upwards.

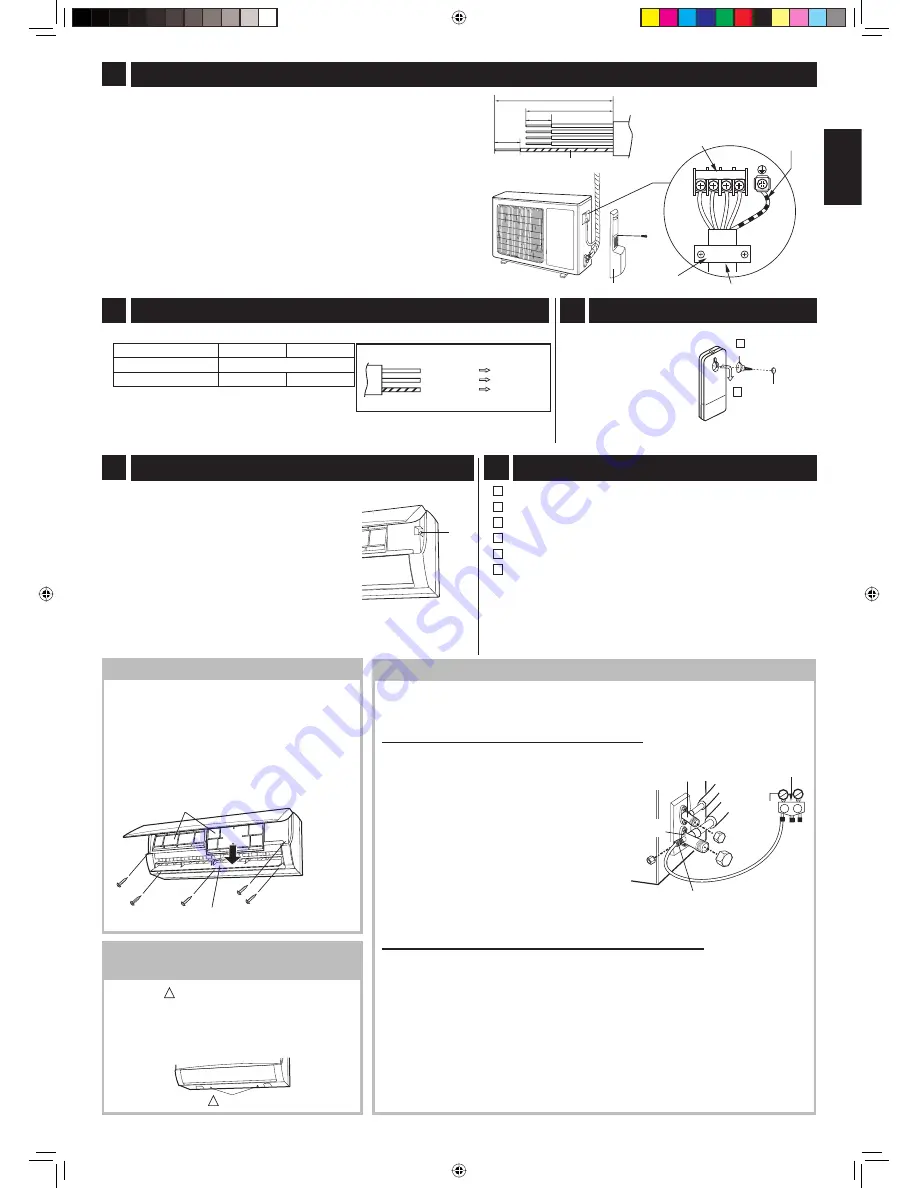

(1) Process the end of the connecting cable for the outdoor unit.

(2) Remove the control box cover.

(3) Remove the cable holder and connect the cable.

Be sure that the terminal connections are as speci

fi

ed.

(4) Fix the cable sheath with the cable holder and the screw.

(5) Double-check that the cable is securely in place.

(6) Put back the control box cover.

Caution:

• Be sure to put the cable leads deep into the terminal board and

tighten up the screws. Poor contact can cause overheating or

fi

re, or malfunction.

• Be sure to connect the cable to match the markings on the out-

door unit’s terminal board and those of the indoor unit.

Earth wire

Control box cover

Connecting cable

Terminal board

Cable holder

Screw

Power supply cable

Blue

Brown

Green/Yel-

low-striped

Power supply

Neutral

Live

Ground

AUX

Prepare a dedicated power supply circuit.

AY-AP9NR

AY-AP12NR

Supply power

220 V - 240 V, single-phase

Circuit breaker

10 A

15 A

8 CONNECTING THE CABLE TO THE OUTDOOR UNIT

9 POWER CABLING

11 TEST RUN

(1) Start the operation with the remote control.

(2) To start test run in cooling, hold down the

AUX button on the unit for over 5 seconds

until a beep sound is heard and an opera-

tion lamp

fl

ashes.

(3) To put the system in the heating test run

mode, select heat mode on the remote

control while the unit is in cooling test run

mode.

(4) Make sure the system runs well. To stop

the operation, press the AUX button again.

12 ITEMS TO CHECK

Is the speci

fi

ed power supply voltage used?

Is the connecting cable

fi

xed to terminal board

fi

rmly?

Is the earth wire connected properly arranged?

Is the drainage properly?

Is the indoor unit hooked to the mounting plate

fi

rmly?

Is there any gas leakage at the pipe connection?

Explanation to customer

• Explain to the customer how to use and maintain the system, refer-

ring to the operation manual.

• Ask the customer to carefully read the operation manual.

• When the system has been set up, hand the installation manual to

the customer.

• Fit a disconnect switch, having a contact separation of at least 3mm in all

poles, to the electricity power line.

Earth wire

“

“ mark

10 HANGING THE REMOTE CONTROL

DETACHING THE FRONT PANEL

(1) Remove the air

fi

lter.

(2) Open the vertical air

fl

ow louvre by hand.

(3) Unscrew the 5 screws of the front panel.

(4) Remove the front panel.

Slightly open the lower part of the front

panel, and extract the 5 hooks along the

upper surface for disassembly.

Screw

Vertical air

fl

ow louvre

Air

fi

lter

(1) Fit the special

screw to the wall

with the wall plug.

(2) Hang the remote

control to the screw

head.

6

SPECIAL

SCREW

2

WALL PLUG

PUMP DOWN

Pump down is adopted in the case of unit removal for re-installation,

abandonment, repair etc. Pump down is to collect the refrigerant into the

outdoor unit.

PROCEDURE USING GAUGE MANIFOLD

(Recommended procedure)

(1) Connect the gauge manifold hose to the

service port of the 3-way valve.

(2) Run the air conditioner at cooling test run

mode (Refer to 11 TEST RUN).

(3) After 5-10 minutes, close the 2-way

valve.

(4) Close the 3-way valve when the com-

pound gauge reading becomes almost 0

MPa(0 cmHg).

(5) Stop the test run operation.

(6) Disconnect the gauge manifold hose

from the service port.

(7) Disconnect both refrigerant pipes.

PROCEDURE WITHOUT USING GAUGE MANIFOLD

(1) Run the air conditioner at cooling test run mode (Refer to 11 TEST RUN).

(2) After 5-10 minutes, fully close the 2-way valve by turning the hexagon

wrench.

(3) After 2-3 minutes, immediately close the 3-way valve fully.

(4) Stop the test run operation.

(5) Disconnect both refrigerant pipes.

Caution:

• Make sure that the compressor is turned off before removing the refrigerant

pipes. Otherwise, it will cause burst and injury.

• Do not perform PUMP DOWN when refrigerant is leaking or there is no refrig-

erant in the refrigerant cycle. Otherwise, it will cause burst and injury

Gauge manifold

Compound

gauge

3-way valve

2-way valve

Service port

04_A3AYAP9_2NR.indb GB-4

04_A3AYAP9_2NR.indb GB-4

2012-01-12 20:45:12

2012-01-12 20:45:12