GB-3

Flaring the pipe end

(1) Cutting with a pipe cutter

Cut at a right angle.

(2) Deburring

Allow no cuttings in the pipe.

(3) Putting in the

fl

are nut

For liquid pipe of the indoor unit side, use the

fl

are

nut included in the accessories.

(4) Flaring

Flare processing dimensions(A)

Tool

A

R410A tool

0 - 0.5 mm

Conventional tool 1.0 - 1.5 mm

(5) Checking

To

be

fl

ared perfectly circular.

Flare nut not missing

.

Not running wavy.

Not left in water.

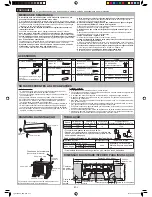

6 CONNECTING THE REFRIGERANT PIPES

Flare nut

No trap

allowed.

Not to rise.

Connecting the drain hose

(1) Connect a drain hose.

(2) Tape over the connecting

part.

ø17 mm

Connecting the pipes

Connect the pipes for the indoor unit

fi

rst and then for the outdoor unit.

For indoor unit, remove sealing cap from the liquid pipe end.

(1) Tighten the flare nuts by hand for the

fi

rst 3-4 turns.

(2) Use a wrench and torque wrench to

tighten up the pipes.

• Do not over tighten the pipes. It may

be deformed or damaged.

4 CONNECTING THE DRAIN HOSE TO THE INDOOR UNIT

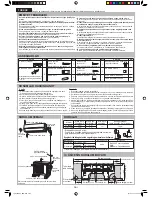

7 AIR REMOVAL

No trap allowed.

90°

A

Lo

Hi

Notes:

• Be sure to lay the drain hose downward for smooth drain

fl

ow.

• Be careful not to allow the drain hose to rise, form a trap or leave

its end in water, as shown below.

• Coil thermal insulation around a drain hose extension, if running in

the room.

Use a vacuum pump, gauge manifold and hoses exclusively for R410A.

(1) Remove both valve shaft caps of the 2 and 3-way valves.

(2) Remove the service port cap of the 3-way valve.

(3) Connect the gauge manifold hose to the service port and the

vacuum pump.

Be sure that the hose end to be connected to the service port has a

valve core pusher.

(4) Open the gauge manifold low-pressure valve(Lo) and operate the

vacuum pump for 10-15 minutes.

Make sure the compound gauge reads -0.1 MPa(-76 cmHg).

(5) Close the gauge manifold valve.

(6) Turn off the vacuum pump.

Leave as it for 1-2 minutes and make sure the needle of the com-

pound gauge does not go back.

(7) Open the 2-way valve 90° counterclockwise by turning the hexagon

wrench. Close it after 5 second, and check for gas leakage.*

(8) Disconnect the gauge manifold hose from the service port.

(9) Fully open the 2-way valve with hexagon wrench.

(10) Fully open the 3-way valve with hexagon wrench.

(11) Firmly tighten the service port cap and both valve shaft caps with a

torque wrench at the speci

fi

ed tightening torque.

* Check the pipe connections for gas leak using a leakage detector or

soapy water. Regarding leakage detector, use high-sensitivity type

designed specially for R410A.

540

286

Gauge manifold

Compound gauge

Vacuum pump

Service port cap

3-way valve

Valve shaft cap

Valve shaft cap tightening torque

Pipe size

Torque

Liquid side 1/4"

24±3 N · m (2.4±0.3 kgf · m)

Gas side

3/8"

AE-A9NR

24±3 N · m (2.4±0.3 kgf · m)

1/2"

AE-A12NR

31±3 N · m (3.1±0.3 kgf · m)

Service port cap tightening torque

Torque

11±1 N · m (1.1±0.1 kgf · m)

Installation dimension

Referring to the

fi

gure,

fi

rmly fasten the

outdoor unit with bolts.

5 OUTDOOR UNIT INSTALLATION

Checking drainage

(1) Open the open panel.

(2) Remove the air

fi

lters.

(3) Pour some water into the

drain pan.

(4) Check the water drains

smoothly.

Connecting the drain hose

In the heating mode, the unit discharged

water from its drain port. Connect a drain

hose if drainage is necessary.

Note:

In cold regions, do not use a drain hose

as it may be frozen.

Drain hose

(Commercially available)

Drain port

9

DRAIN HOSE

ADAPTER

Wrench

Torque wrench

2-way valve

Hexagon wrench

(Diagonally 5 mm)

OPEN

Service port

CLOSE

Flare nut tightening torque

Pipe size

Torque

Liquid side 1/4" (ø 6.35 mm)

16±2 N·m (1.6±0.2 kgf·m)

Gas side

AY-AP9NR

3/8" (ø 9.52 mm) 38±4 N·m (3.8±0.4 kgf·m)

AY-AP12NR

1/2" (ø 12.7 mm) 55 ± 5 N·m (5.5 ± 0.5 kgf·m)

Drain hose

(Commercially

available)

Bottom frame

04_A3AYAP9_2NR.indb GB-3

04_A3AYAP9_2NR.indb GB-3

2012-01-12 20:45:10

2012-01-12 20:45:10