11

MAINTAINING THE MECHANISM

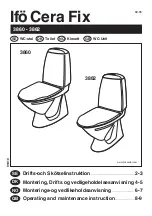

(fig.11.b)

(cleaning or replacing the sealing joint)

Follow the same steps as for maintaining the tap until

step 6, then:

1 -

Grip the mechanism by its base and remove it

from the cistern.

Replacement parts:

Sealing joint : Réf. 34 2332-07

Whole mechanism : Réf. 32 4544-07

2 -

Once maintenance has been completed, carry out

the steps in reverse order.

In order to ensure that the mechanism is correctly

repositioned, its base is fitted with a foolproofing

device.

MAINTAINING THE MACERATOR

L’appareil The unit requires no special maintenance. The

unit is equipped with an active carbon filter in the vent. It

is not required to be connected to an external vent. This

filter should be replaced every year.

CLEANING/DESCALING

Regularly use an appropriate descaling agent such as

SFA

SANIBROYEUR to descale and clean the

macerator and the bowl. This product is specially

designed to remove scale whilst respecting the

internal workings of your unit.

• Disconnect the macerator power supply.

• Pour a measure of descaling agent into the bowl.

• Leave it to stand for a few hours.

• Reconnect the macerator power supply.

• Rinse by flushing twice.

This should be carried out every three months on

average, but you may need to adjust this schedule

depending on the hardness of your water.

MAINTENANCE

Some basic maintenance may be necessary during

normal usage of your

SANIWALL

®

Pro

.

MAINTAINING THE TAP

(fig. 11.a)

(cleaning the filter, changing the membrane)

1 -

Remove the flush plate by gently lifting it up and

then tilting it forwards.

2 -

Remove the plate’s actuation screw.

3 -

Unscrew the screws on the small backplate and

remove this.

4 -

Remove the frame as shown in

7.3.a

.

5 -

Turn off the stop tap and separate it from the

ballcock .

6 -

Rotate the spacer supporting the ballcock and re

move this.

7 -

Once the maintenance is complete, carry out

the above steps in reverse order, remembering to

turn the stop tap .

Replacement parts:

Membrane : Réf. 34 9513-07

Whole tap : Réf. 30 9503-07

u

d

d

11.a

11.b

11.c

11.d

USAGE AND PRECAUTIONS

Toilets installed with a

SANIWALL

®

Pro

are to be used

just like any traditional toilet and require no special

maintenance. The macerator is automatically activated

once water reaches a certain level in the unit.

The

SANIWALL

®

Pro

macerator is designed to

discharge toilet, washbasin and shower waste.

IT IS NOT INTENDED FOR EITHER COMMERCIAL OR

INDUSTRIAL USE.

WARNING!!! If away for long periods (e.g. holidays),

we recommend that you turn off the water supply to

the unit.

WARNING!!! Should the unit be used to discharge

anything other than toilet paper, faecal matter or

waste water the guarantee will be invalidated. Any

damage to the unit caused by maceration of foreign

bodies such as cotton, tampons, sanitary towels,

wipes, food products, condoms, hair, metal wood or

plastic objects, or by pumping liquids, such as

solvents and oils, will not be covered by the

guarantee.

10

ACTIVATING THE UNIT

Once all electrical and plumbing installations are

complete, flush the unit once. The unit should start

automatically and run for between 5 and 10 seconds

depending on the height of the discharge pipe. If it runs

for more than 20 seconds, check that the discharge

hose is not kinked (causing a blockage) or that the vent

is not blocked.

Flush several times. All pipes must be watertight. At the

same time, if necessary, check the watertightness of

connections to any other sanitary appliances (e.g.

washbasin).

WARNING!!! The flushing system (as well as any other

sanitary appliances connected to the macerator) must

be completely watertight. Even a small leak could

cause the macerator to be activated unnecessarily.

9

STANDARDS

This appliance complies with EN 12050-3 (Lifting plant for

waste water containing faecal matter for limited applications)

and the European directives and standards concerning

electrical safety and electromagnetic compatibility.

8

Notice SANIWALL PRO Traduction_1:Mise en page 1 23/09/2008 12:25 Page 19