-EN_9 -

A u t o f i l l

SL310010085 Ed.00 - 03_14

7. CLEANING

AND

MAINTENANCE

Before undertaking any cleaning and maintenance of the

Autofill’s external components, make sure that the main

switch is positioned on -0- and that the machine is un-

plugged.

The procedures recommended below do not re-

lease the user from his responsibility to prop-

erly and regularly treat equipment according

to the specific environmental and operational

conditions in the local; the type of installation; the level

of consumption; the chemical and physical properties of

prduct used and any other factors which may promote

the development of microbes.

The user must evaluate all of the above-mentioned fac-

tors carefully and act in compliance with local hygiene

standards and in respect of the health and safety of those

that drink the end-product.

The procedures outlined below should be carried out:

•

upon initial installation;

•

at least every 15 days during normal use;

•

at the end of the season and/or before a long

period of inactivity or storage;

•

before use after a long period of inactivity.

Attention: Also perform the procedures when

the Autofill system has not worked for 3 - 4

days, during normal use, for example because

it did not deliver any granita.

When carrying out cleaning and maintenance jobs, you should

observe the following rules:

•

wear accident prevention protection gloves;

•

do not use solvents or infl ammable materials;

• do not use abrasive and/or metal sponges to clean the ma-

chine and its components;

•

do not wash the machine components in the dish washer;

•

do not immerge the machine into water;

•

do not spray direct water jets on the equipment;

•

take care to avoid dispersing liquids in the surrounding area;

•

do not dry parts of the Autofi ll in a conventional and/or micro-

wave oven;

•

use only a cloth dampened with water to clean external parts.

•

use only lukewarm water and a proper disinfectant for clean-

ing (a 5% water-based solution of sodium hypochlorite), so

that the machine components are not damaged;

• at the end of the operations, correctly reset and fi x all the

protections which had been removed or opened.

Do not use any other method and/or liquid to clean

the Autofi ll system.

Never perform cleaning or maintenance jobs on

the Autofi ll when it is plugged in and the main

switch is positioned on -1-. Before cleaning the

Autofi ll, you should also turn off and unplug the

slush machine.

7.1. Cleaning the product circuits

In order for you to perform cleaning and maintenance jobs

on the internal circuits of the Autofi ll, it must be plugged in

and the main switch must be positioned on -1-.

The sanitizing solution and the water used for

cleaning must be collected in a suitable container.

If you intend to replace the product inside the tank,

you can dispense the sanitizing solution directly

into the tank itself. First you must empty the tank

of all its contents and after cleaning you must

empty it of the liquids introduced with the Autofi ll.

The product circuits must be cleaned and sanitized

every time the product fl avor is changed and in any

case at least once a week following the initial load-

ing of the circuit.

Circuits must be anyhow cleaned and sanitized ac-

cording to what prescribed by the hygienic stand-

ards in force in the country where the Autofi ll sys-

tem is used.

NOTE: In normal working conditions, the prod-

duct pump silicone pipe shall be replaced every 6

months.

To sanitize the product circuit, proceed as follows:

1. Turn off the Autofi ll by moving the main switch to “0”;

2. Remove the intake tube from the product container; wash the

intake tube with lukewarm water (40°C);

3. Turn on and keep working the Autofi ll until all the product has

come out of the Autofi ll product dispensing tube

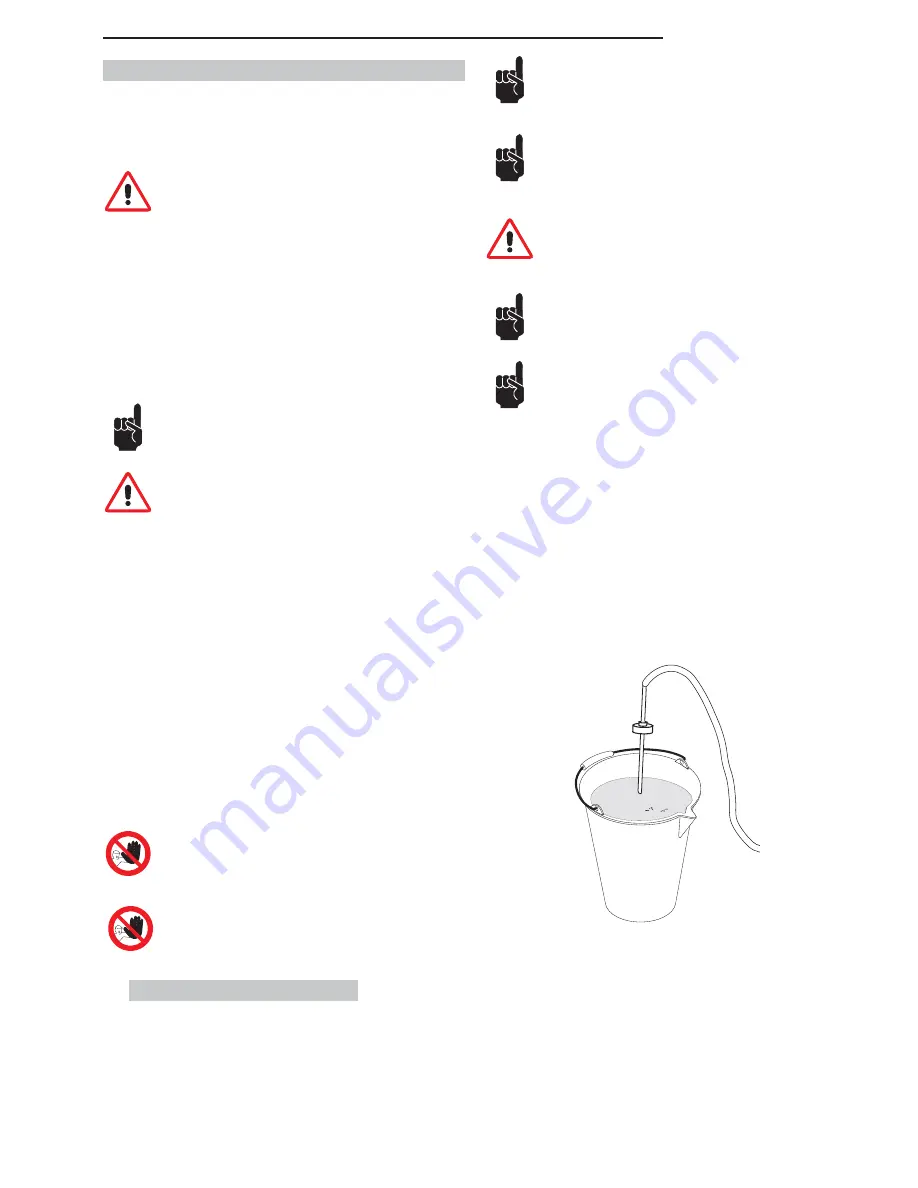

4. Insert a container of lukewarm water (40°C) in place of the

product container and place the previously emptied product

intake tube inside it.

5. Turn on and keep working the Autofi ll until the water coming

out of the product dispensing spout is perfectly clear, without

traces of product.

Then insert the intake tube in a container of sanitizing solution (a

5% water-based solution of sodium hypochlorite).

1. Turn on and keep working the Autofi ll until you see sanitizing

solution start to come out of the Autofi ll.

Allow ten (10) minutes for the sanitizing solution to act; Then fl ush

out the circuit with lukewarm water to remove the sanitizing solu-

tion:

1. Wash the intake tube with potable water (40°C);

2. Thoroughly wash the container and fi ll it with potable water

(40°C);

3. Insert the intake tube in the container of water;

4. Turn on and keep working the Autofi ll, so that plenty of water

comes out and the sanitizing solution is removed.

Fig.11