29

508.366.1488 | www.semshred.com

10.

Torque bed knives to 45-50 ft./lbs.

o

Requires torque 5/16” Allen drive socket bit.

o

Torque wrench should not be used as a socket wrench and should be calibrated to ensure proper

tightening to avoid damage. SEM offers a complete toolkit for this system.

o

Double check knife clearance after torqueing bolts.

11.

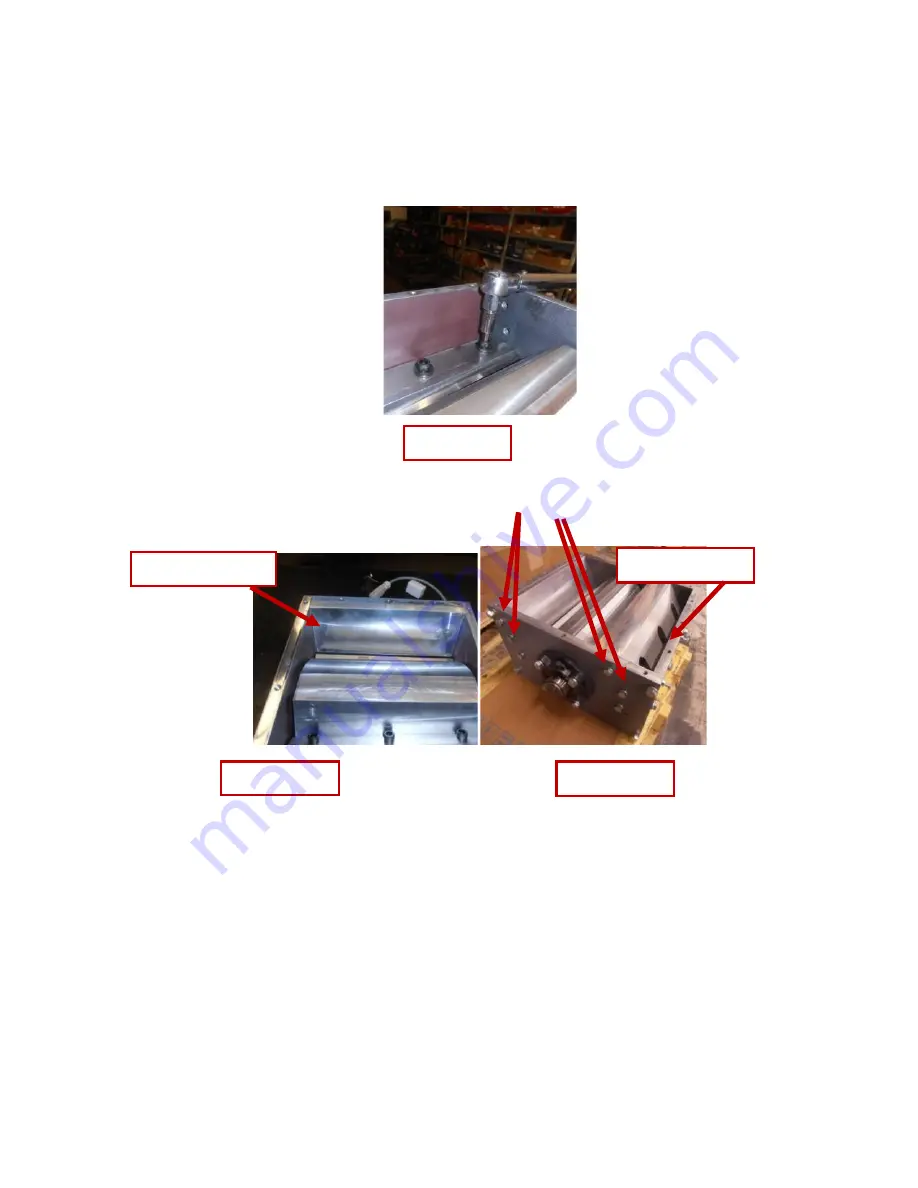

Attach front and rear deflectors as shown with eight 5/16”-18 x 1 1/4" hex bolt and 5/16” lock washer.

Requires 1/2" wrench

12.

Do a final check of bolt torques, assembly bolt tightness, and knife gapping.

Warning:

Failure to sharpen or replace knives will result in excess dust, frequent jamming of stage 2 chamber,

reduced throughput, excess vibration, and increased noise throughout the device.

Re-sharpening:

Knives can be re-sharpened 2-3 times provided they are not significantly damaged or worn. Knives

must be sharpened as a complete set

(two bed knives, three rotor knives). Contact SEM Customer Service for

details or for replacement knives.

Front Deflector

Rear Deflector

Figure 10

Figure 11

Figure 12