CYLINDER HEAD, CYLINDER, PISTON

CYLINDER HEAD, CYLINDER, PISTON

3-5-29

B

B

A

A

◆

Measure the free length of each valve spring with

a vernier caliper and compare it with the standard

value.

◆

Free length of valve spring:standard:1.726" (43.85

mm)

,

service limit:1.683" (42.75 mm)

Standard

Limit

42.5 mm (1.6732")

41.4mm (1.6299")

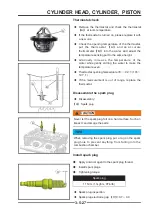

Valve guide / valve inspection

◆

Valve stem clearance measurement:

If there is no small aperture gauge, use the swing method

to measure the gap between the valve and the valve

guide and check the wear of the valve guide. The method

is as follows.

◆

Insert a new valve

【

A

】

into the valve guide

【

B

】

,

and place a dial indicator perpendicular to the valve

stem on the valve stem, as close as possible to the

cylinder head mating surface.

◆

Swing the valve lever to measure the valve/valve

guide gap.

◆

Repeat the measurement in the direction at right

angles to the first direction. If the reading exceeds

the use limit, replace the cylinder head and camshaft

cover assembly.

TIPS

The reading is not the true gap between the valve and

the valve guide, because the measurement position is

above the guide.

Valve/valve guide clearance (swing method)

Standard

Limit

exhaust:

0.09 ~ 0.17 mm(0.0035" ~ 0.0067")

0.34 mm

0.0133"

Air intake:

0.03 ~ 0.11 mm(0.0012" ~ 0.0043")

0.28 mm

0.0110"

◆

Measure the beating, pitting and ablation of the

valve stem. Check whether the valve rod is bent,

clamp the valve on the machine tool or use a "V"

block and measure it with a dial indicator.

◆

Check whether there is flaring, pitting, abrasion or

damage at the end of the valve stem.

◆

Check whether there is flaring or abrasion at the

lock clip groove. .

Top

bottom

Summary of Contents for S301000-20100A

Page 1: ...SERVICE MANUAL SSV 4 3 4 130 6 54...

Page 50: ...ENGINE LUBRICATION SYSTEM 3 1 2 Exploded view...

Page 63: ...EFI SYSTEM 3 2 2 Exploded view Exploded view...

Page 67: ...STARTING SYSTEM 3 3 2 Exploded view...

Page 75: ...CRANKCASE CRANKSHAFT BALANCE SHAFT 3 4 2 Explosive view...

Page 76: ...CRANKCASE CRANKSHAFT BALANCE SHAFT 3 4 3 Explosive view of Up and down the case sub assembly...

Page 100: ...CYLINDER HEAD CYLINDER PISTON CYLINDER HEAD CYLINDER PISTON 3 5 3 Exploded view...

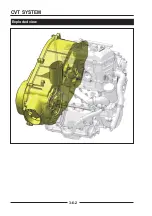

Page 141: ...CVT SYSTEM 3 6 2 Exploded view...

Page 151: ...WATER PUMP ASSEMBLY 3 7 2 Exploded view...

Page 197: ...6 6 COOLING SYSTEM SPECIAL TOOLS AND SEALANTS Silicone Sealant Special tools and sealants...

Page 227: ...9 2 FRONT REAR SUSPENSION EXPLODED VIEW OF FRONT SUSPENSION...

Page 229: ...9 4 FRONT REAR SUSPENSION EXPLODED VIEW OF REAR SUSPENSION...

Page 247: ...10 5 WHEELS AND TIRES SPECIAL TOOLS Jack...

Page 261: ...11 4 BRAKE SYSTEM SPECIAL TOOLS Inside Circlip Pliers...

Page 314: ...14 4 ELECTRICAL SYSTEM EXPLODED VIEW...

Page 407: ...14 97 ELECTRICAL SYSTEM ELECTRIC SCHEMATIC DIAGRAM...