34

13.5 Planer Tables

The surface tables are formed from cast iron, and may become warped or bent as a result of

neglected maintenance and excessive wear. The dust and vibration from surfacing miles of hard

maple or pitch pine, will loosen adjustments and make slideways sticky. A sloppy fit hammers

adjoining precision surfaces, and poorly lubricated slideways wear quickly. Never place anything

on these tables which doesn’t belong there. An excessive weight laid to rest on a table could,

over time, cause the table to sag, necessitating a re-grind. Also take great care when handling

the machine (refer to Handling Instructions). Any attempt to lift or drag the machine by its top

tables could result in them coming out of true.

If at any time you suspect that your top tables are out of true, first check them for flatness

using a long straightedge. Raise the infeed table until it is level with the outfeed table. Check

the individual tables first, longitudinally for parallelism and then diagonally for flatness.

Measure any space under the straight edge with an engineer’s feeler gauge - any gap should be

less than 0.010 in. Next, check both tables as a unit. Check next to the fence and on the

opposite side, and then check the diagonals for twist. Ideally the tables should be less than

0.010 in. out of parallel end to end.

Should you find that adjustment is necessary, begin by removing the infeed table (sometimes

dirt between the slideways can build up and cause alignment problems). Clean all surfaces and

lubricate with a light lithium grease. Reassemble using a 19mm AF Spanner to tighten the gib

screws. If they are not tightened correctly the table will sag at the end. If they are over

tightened the table will not rise and fall. The rise and fall action should only require moderate

action.

If this method fails to align the tables, shim underneath the feet of the fixed outfeed table until

it is aligned with the infeed table at its highest point. Brass or sheet steel shim stock is the best

choice for this.

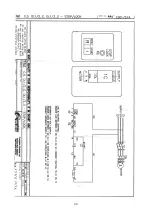

13.6 The Fence

The squareness of the fence relative to the infeed table is adjusted via a back stop. First

tighten the fence lateral lock, untighten the fence cant lock, and push the fence into the

vertical. Use an engineer’s square to check the angle between the fence and the infeed table. If

necessary release the 8mm lock nut at the back of the fence using a 13mm spanner, and adjust

the stop using the 4mm allen key supplied.

Summary of Contents for PT255

Page 36: ...36 14 0 PT255 Planer Thicknesser Parts Diagram ...

Page 39: ...39 ...

Page 40: ...40 ...