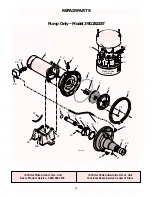

REPAIR PARTS

13

Key

Model 390.252157

Part

No.

1/2 HP

Description

1**

J218-953C

Motor - 1/2 HP - 115/230V - 60 Cycle

(Includes Key Nos. 1A through 1E)

1A

U18-1103

Overload Protector

1B

U18-1180

Terminal Board

1C

U18-1098

Contactor

1D

U18-128

Governor

1E

U18-526

Capacitor

2

C69-2

Water Slinger

3*

U78-107PT

Reducer Bushing - 1/2” x 1/8” NPT

4

WC78-41T

Pipe Plug - 1/8” NPT

5

L176-47P

Tank Body (Back Half)

6

U9-399

“O” Ring - Tank Body - 9-1/2” x 9” x 1/4”

7

U109-6A

Shaft Seal

8

J105-40PE

Impeller

9

J1-39P

Diffuser

10

C19-54SS

Clamp - Tank Body

11

U9-201

“O” Ring - Venturi - 1-3/8” x 1-1/8” x 1/8”

12

N32P-66

Venturi

13

N34P-19

Nozzle

14

N76-29P

Insert

15

J20-18

Gasket

16

N176-28PB

Tank Body Assembly (Front Half - Includes

Key No’s. 11, 12, 13, 14, 15, 16, 19, 20, 21, 23 and 24)

16

N76-28P

Tank Body Only - Front Half

17

U37-673P

Switch Tube

18

U111-212T

90° Hose Barb

19

U9-226

“O” Ring - Check Valve - 2-1/4” x 2” x 1/8”

20

N166-5P

Check Valve

21*

WC78-41T

Pipe Plug - 1/8” NPT (2 Required)

22

U212-68T

Draincock - 1/4” NPT

23

U30-742SS

Screw - #10 - 16 x 1-1/8” (4 Required)

24

U30-542SS

Screw - #8 - 32 x 7/8” (5 Required)

25

C4-42P

Base

26*

U36-37ZP

Nut - 5/16” - 18 Hex Head (4 Required)

26A

U43-11ZP

Lockwasher (4 Required)

27

C35-11

Motor Pad

28

2782

Pressure Switch

29

U36-112ZP

Locknut - 1/2”

30

L43-5C

Connector

* Standard hardware item, may be purchased locally.

** For repair or service to motors, always give the motor model number.

Summary of Contents for CRAFTSMAN 390.252157

Page 15: ...15...