3

SAFETY INSTRUCTIONS (Continued)

Pump

Discharge

Pumping Depth in Feet

Model

Description

Suct.

Disch.

Pressure PSI

5’

10’

15’

20’

390.252157

1/2 HP S.W. Jet

1-1/4”

1”

40

8.2

7.3

6.2

5.0

TABLE I – Pump Performance (In Gallons per Minute)

NOTE: This system is designed for pumping depths of 20 feet or less.

6. Disconnect electrical power source before installing or

working on pump.

7. Ground pump with a ground wire run from grounding

lug on motor to a grounded lead in the service panel.

8. Line voltage and frequency of electrical power supply

must agree with motor nameplate.

9. Use of fuses or wire smaller than size recommended in

owner’s manual can cause overheating, possible fires,

and will void warranty.

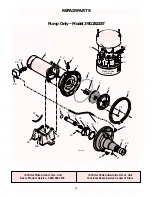

Impeller and Jet

Impeller turns with motor shaft, causing water to fly out

from its rim by centrifugal force. Impeller rotation creates a

vacuum which pulls in more water. Part of the water is di-

verted back to the jet where it passes through the nozzle and

venturi. This creates more vacuum to draw in more water.

In shallow wells (less than 20 feet deep), the vacuum cre-

ated at the pump is enough to pull water to the pump.

Therefore, for shallow well use the jet is built into the pump.

Pre-Charged Tank

The tank serves two functions. It provides a reservoir of

water under pressure and maintains a cushion of air pres-

sure to prevent pipe hammering and possible damage to

plumbing components. When water is drawn off through

the house fixtures, the pressure in the tank is lowered and

the pump starts.

Pressure Switch

The pressure switch provides for automatic operation.

Pump starts when pressure drops to 40 pounds and stops

when pressure reaches 60 pounds.

Check Valve or Foot Valve

This pump is equipped with a built-in check valve. Install a

check valve

as close to well as possible

on well point in-

stallations. A foot valve must be installed

in the well

on dug

or cased wells. See Figures 2A and 2B, Page 4. For long hor-

izontal pipe runs, install check valve as close to well as pos-

sible (all types of wells).

BASIC TOOLS AND MATERIALS NEEDED

Plastic Pipe Installation

Tools

Materials

Pipe Wrenches

Plastic Pipe and Fittings (as required to complete job).

Screwdriver

Knife or Saw to Cut Plastic Pipe

Teflon Tape (DO NOT use joint compound on plastic fittings).

Tire Pressure Gauge

Galvanized Steel Pipe Installation

Tools

Materials

Pipe Wrenches

Galvanized Pipe and Fittings (as required to complete job).

Screwdriver

Pipe Cutting and Threading Tools

Pipe Joint Compound or Teflon Tape

Tire Pressure Gauge

MAJOR COMPONENTS AND WHAT THEY DO

Summary of Contents for CRAFTSMAN 390.252157

Page 15: ...15...