26

Mooring Bridle Assembly:-

• All welding is to comply with the requirements of AS1554.1 “Structural Steel Welding

Nominal tensile strength of weld metal (filler) is to be 450MPa or greater.

• Weld category GP (general purpose).

• Inspect welds visually in accordance with AS1554.1 “Structural Steel Welding – Welding

Steel Structures” Section

Additional locking pins can be fabricated from Ø6 Round Rod, Grade 316 Stainless Steel or better.

4. If the Ø44 Grade S shackles are of standard pin type, then it is recommended that

shackles are welded shut.

•

8mm circumferential fillet weld around head of pin, 3 places.

5. Turn the whole bridle assembly over (weight of the bridle assembly is around 175 kg).

•

6mm flush weld around tail end of pin, 3 places.

6. Turn the whole bridle assembly back over (shackle pin heads should be on top).

4. If the Ø44 Grade S shackles are of the safety pin type (with nut and cotter pin), then it is

recommended that each shackle has an additional Ø6.5 hole drilled through the nut and

pin and an additional Ø6 locking pin fitted for added connection security (turn the whole

bridle assembly over for ease of access).

5. Reposition so that shackle pin heads are on the under-side (turn the bridle assembly

over if necessary).

SAFETY PIN SHACKLES

Summary of Contents for ATLANTIC-3000

Page 2: ...2 Version No Description Date Author Approved 1 0 Manual Launch October 2018 G Percy G Percy ...

Page 8: ...8 Technical Drawings ...

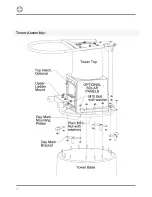

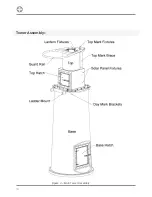

Page 14: ...14 Tower Assembly ...

Page 16: ...16 Tower Assembly Figure 4 Main Tower Assembly ...

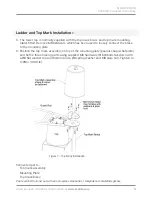

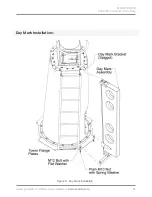

Page 20: ...20 Ladder and Top Mark Installation Figure 6 Ladder Installation ...

Page 32: ...32 Electronic Equipment Installation ...

Page 34: ...34 Notes ...