www.seagullmodels.com

9

3) Peel off the backing from the self adhe-

sive covering strip. Apply the strip to the centre

section of the wing starting from the bottom

trailing edge. Wrap the strip all the way around

the wing until it meets the trailing edge again.

Trim off any excess strip.

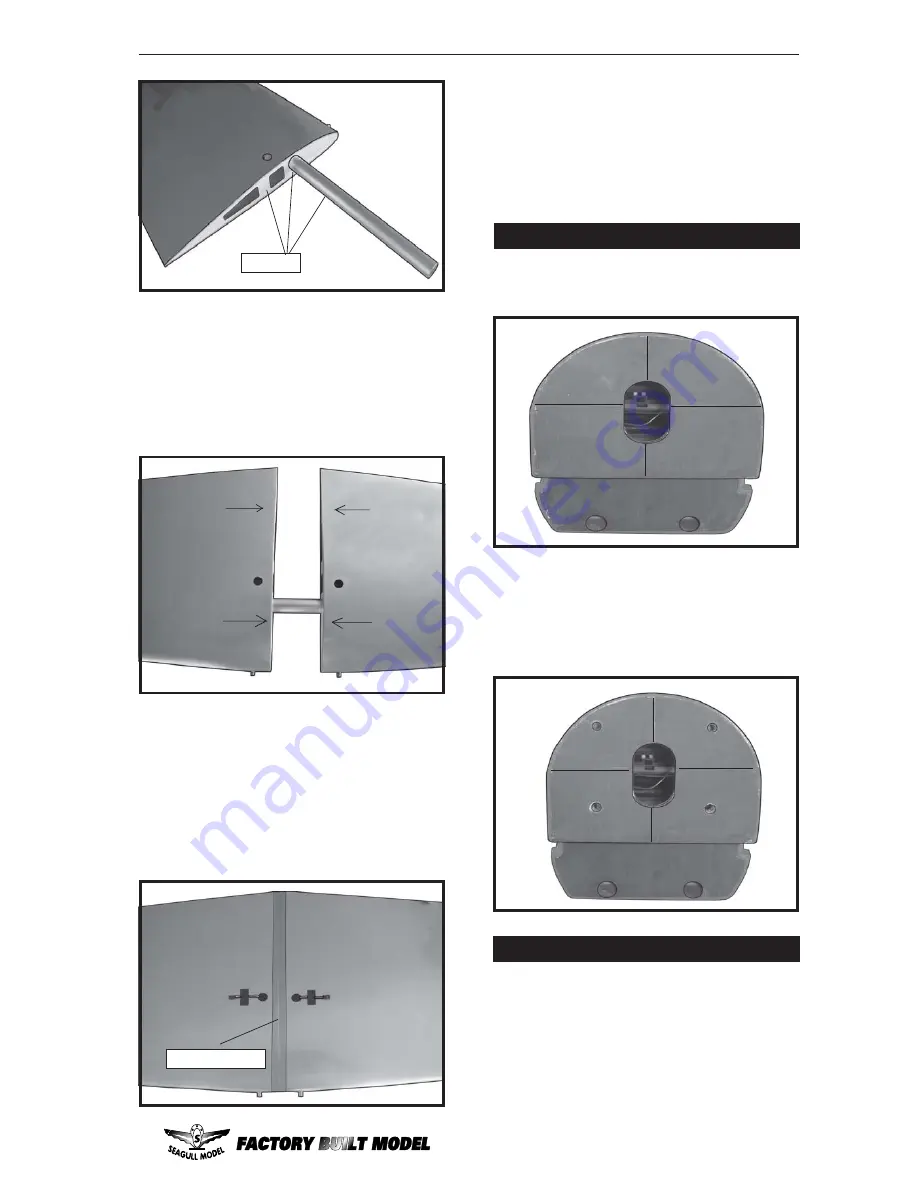

Carefully slide the two wing halves together

and firmly press them together, allowing the

excess epoxy to run out. There should not be

any gap in the wing halves. Use rubbing

alcohol and a paper tower to clean up any

excess epoxy.

Apply masking tape at the wing join to hold

the wing halves together securely.

2) Remove the brace when satisfied with

its fit ineach wing half. Coat the dihedral brace

with 30 minute epoxy. Next, pour some epoxy

into the dihedral box in one wing panel. Make

sure you cover the top and bottom as well as

the sides of the dihedral brace.Use enough

epoxy to fill any gaps.

Masking tape.

1) Install the pushrod housing through the

predrilled hole in the firewall and into the servo

compartment. The pushrod housing should

protrude 1/4" out past the front of the firewall.

Make a Z-Bend 1/4" from one end of the plain

wire pushrod.

MOUNTING THE ENGINE.

Epoxy.

see pictures below.Make yourself the

template of your engine on paper.

ENGINE INSTALLATION.

1) Line up the template with the firewall

thrust line.

2) Engine mouting holes after marking with

the template.Insert the blind nuts (not inclued).