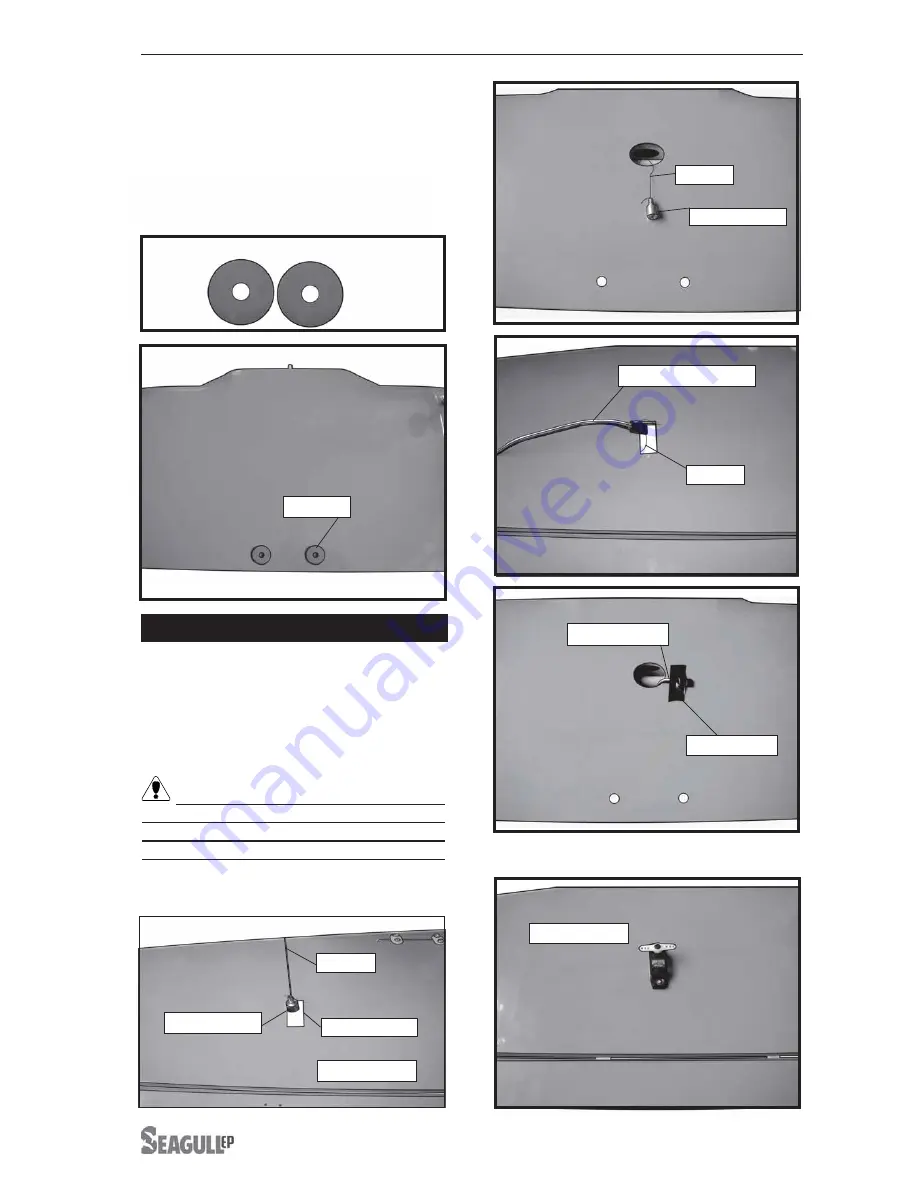

AILERON SERVOS-LINKAGES.

1) Turn the wing panel right side up. Using

a modeling knife, remove the covering at servo

tray.

Attach the thread to the servo lead and

carefully thread it though the wing.

2)Secure the servos with the screws pro-

vided with your radio system.

Install the rubber grommets and brass collets

onto the aileron servo.Test fit the servo into

the aileron servo mount.

Because the size of servos differ, you

may need to adjust the size of the precut open-

ing in the mount. The notch in the sides of

the mount allow the servo lead to pass through.

4) When the epoxy has cured, carefully

remove the masking tape from the wing.

5) Peel off the backing from the self adhe-

sive covering strip. Apply the strip to the centre

section of the wing starting from the bottom

trailing edge. Wrap the strip all the way around

the wing until it meets the trailing edge again.

Trim off any excess strip.

Wing bottom.

Thread.

Servo electric wire.

Electric wire.

Plastic tape.

C/A glue.

Thread.

Servo mount.

Small weight.

Wing bottom.

Thread.

Small weight.

www.seagullmodels.com

7