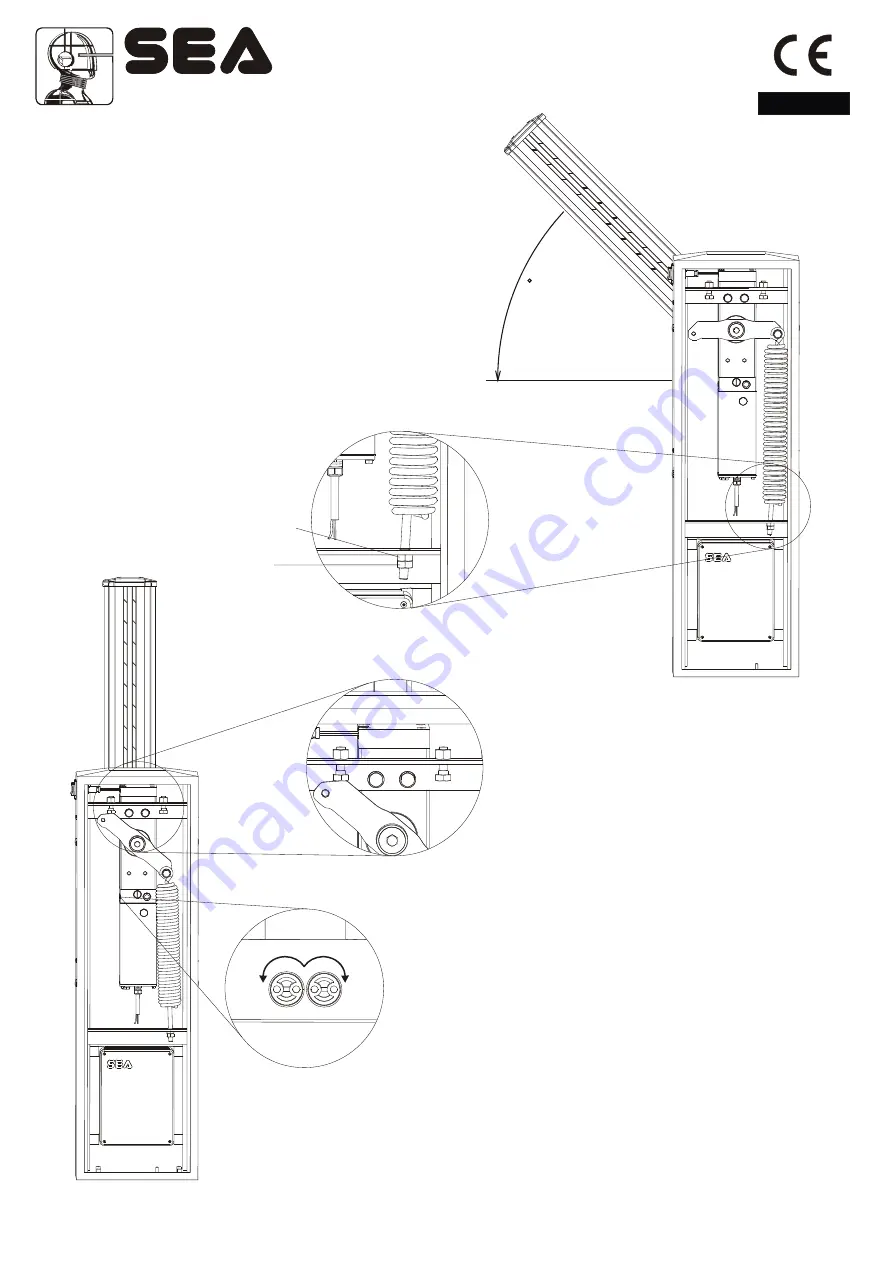

Fig. 14

Fig. 15

5

4

5

4

9) Force adjustment

If necessary the force of thrust of the beam can be

adjusted through the two calibration screws (grey and

yellow) placed on the side of the hydraulic unit

(Fig.16).

*The automation is adjusted at 15 kg force ex works

so to guarantee the anti-crush safety. We recommend

to adjust it only in case of necessity.

Fig.16

-

+

English

8) Beam balancing

-

Release the beam with manual release, so that it is

free to be opened and closed manually (Fig.18).

-

Place the beam at approx. 45°.

-

Loosen or tighten the spring stretching nut until the

spring counterbalances the weight of the 45° beam

(Fig. 14). The best balancing position is obtained when

the beam reaches the position shown in Fig. 14.

-

After having obtained the balancing, lock the nuts of

the spring stretcher with the counter nut and re-block

the motor.

Spring

nut

stretching

Anchoring

lock nut

10) Beam levelling

Note:

this operation must be carried out only if the beam is not

perfectly horizontal (closing stage) or vertical (opening stage) at

the end of its stroke.

-

Release the beam with the special manual release so that it is

free to open and close manually.

-

Release the screws of the limit switch on unscrewing the nuts

on the mechanical stops (fig.15).

-

Loosen or tighten the stop screws so that the beam is released

in its vertical position (opening stage) and horizontal position

(closing stage) (Fig. 15).

-

After having executed the levelling lock the screws of the limit

switch tightening the nuts on the mechanical stops and re-lock

the beam.

Sistemi Elettronici

di Apertura Porte e Cancelli

International registered trademark n. 804888

®

Cod. 67410035 Rev 06 - 06/2010

23