Field Service Procedure – Replacement Pol Pot Kit, 4012

Page

13

of

16

Document No

136829 Rev A

Copyright © Sea Tel, Inc 2012 - The information contained in this document is proprietary to Sea

Tel, Inc. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

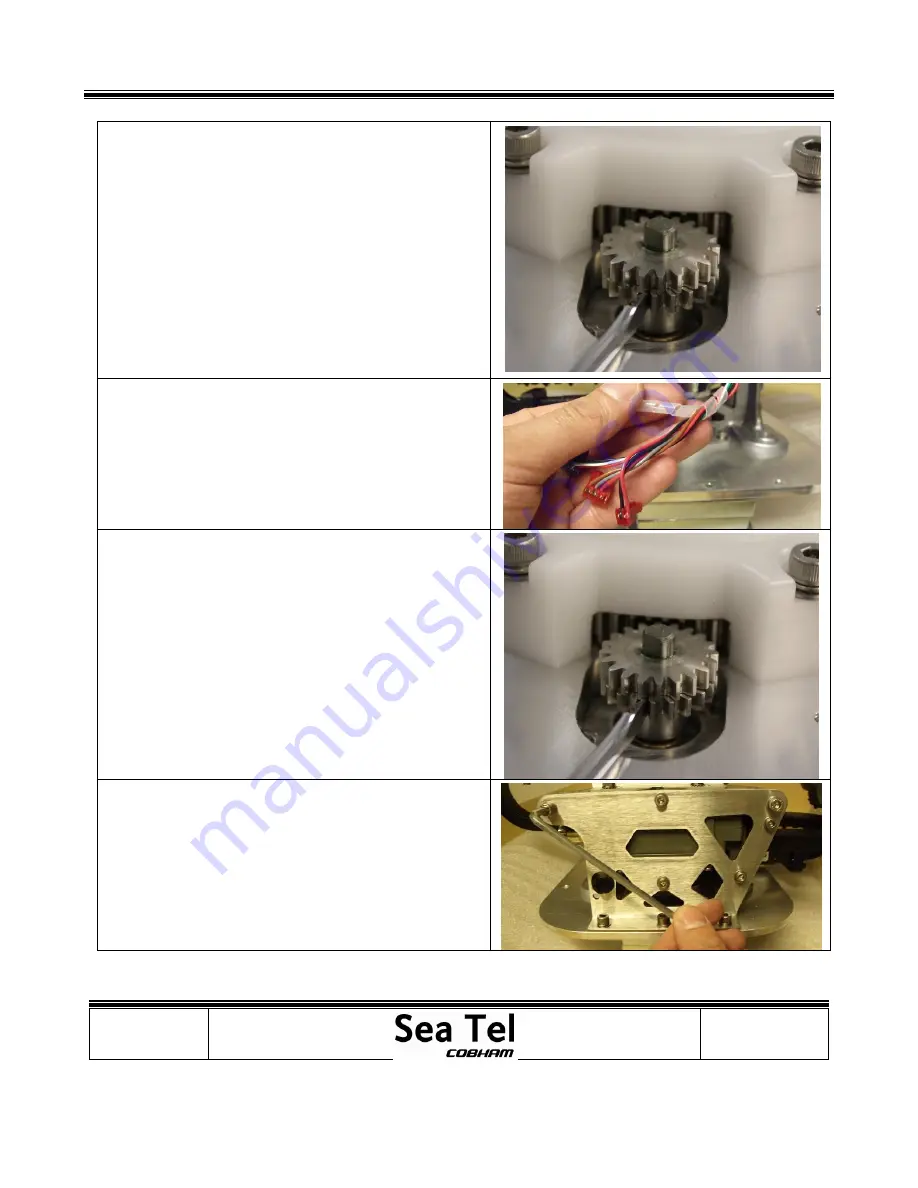

28.

Use

a

screwdriver

to

hold

the

bottom

half

of

the

backlash

gear

(pot

shaft)

steady

while

rotating

the

top

half

CW

one

tooth

(against

the

spring

action)and

push

the

pot

assmebly

forward

to

mate

into

the

driven

gear

in

the

feed.

29.

Hold

tension

against

the

pot

bracket,

and

while

assuring

that

the

pot

resistance

reading

is

still

3050

+/

‐

50

ohms,

tighten

the

mounting

screws.

30.

If

the

pot

resistance

is

not

3050

+/

‐

50

ohms,

repeat

steps

23

‐

29

until

the

proper

reading

is

achieved

at

exact

feed

alignment.

31.

Remove

the

tape

from

the

feed

and

verify

alignment

and

resistance

when

exactly

aligned.

If

correct,

this

completes

calibration

of

the

assembly.

32.

Route

the

pot

wires

throught

the

RF

cage

where

they

will

not

be

pinched

when

re

‐

installing

the

side

bracket

and

install

the

harnesses

back

into

the

wrap

removed

is

step

18.

33.

Flip

the

RF

cage

over

to

expose

the

pol

motor

backlash

gear.

34.

Use

a

small

flat

blade

screwdriver

to

hold

the

bottom

half

of

the

backlash

gear

steady

while

rotating

the

top

half

CW

one

tooth

(against

the

spring

action)and

push

the

motor

assemebly

forward

to

mate

into

the

driven

gear

in

the

feed.

35.

Once

engaged

tighten

the

screws

securing

the

pol

motor

to

the

bottom

plate

of

the

RF

cage

using

a

3mm

Allen

wrench.

Apply

Loctite

242

to

the

threads.

*Note:

Precise

alignment

of

the

feed

is

not

required

when

re

‐

coupling

the

motor.

36.

Install

the

Co

‐

Pol

LNB

and

bracket

assembly

to

the

RF

cage

using

a

the

5

screws

removed

in

step

15

and

a

4mm

Allen

wrench.

Apply

Loctite

242

to

the

threads,

do

not

fullt

tighten

at

this

time.

*Note:

Ensure

the

waveguide

bracket

is

installed

on

the

outside

of

the

flange

so

the

5

mounting

points

align

correctly.

Summary of Contents for 4012

Page 1: ......