Maintenance and Care

26

01.02|SPG 100|en

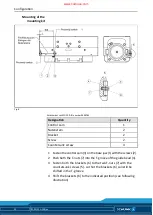

Disassembly of the gripper

Position of the position numbers

WARNING

Risk of injury when the machine/system moves unexpectedly!

Remove the energy supplies.

Make sure that no residual energy remains in the system.

1 Remove the pressure lines.

NOTE

Even after the removal of the pressure lines, the piston chamber

that was last subjected to compressed air will still be under pres-

sure due to the integrated pressure maintenance valve. This

pressure chamber must be bled before the gripper is

disassembled.

2 Open the locking screws (47) in the lid (9) and in the base jaw (2),

until the pressure chamber has been bled.

3 Remove the snap ring (51) and pull the pinion bearing (11) out

of the housing using a screw or an extractor.

4 Remove the pinion (8) from the housing.

5 Pull the cylindrical pins (40) out of the covering plate (10)

using a screw or an extractor.

6 Undo the screws (34) and remove the covering plate (10).

7 Remove both of the snap rings (50) and pull the lid (9) out of

the base jaws (2). If the lid jams, remove the snap ring (52)

and the locking screw (47). The lid (9) can then be pulled out

using a screw or an extractor.

8 Push the base jaws (2) into the position „Gripper closed” and

unscrew the piston (6) out of the base jaws (2) with a face

wrench.

9 Then pull the base jaws (2) out of the guide beads (3).

10 Pull the cylindrical pins (40) out of the piston rod (5) using a

screw or an extractor, remove the screws (32) and then

remove the piston rod (5).

11 Remove both locking screws (17) and the O-rings (24) and press

the pressure maintenance valve (16), or the sealing bolt (12) out

of the piston rod (5).

12 Clean all parts thoroughly and check all parts for defects and

wear.

13 Replace all seals according to the seal kit list.

The gripper is assembled in reverse order.

9.4

www.comoso.com