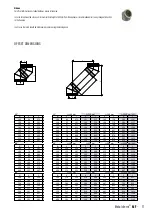

NL 2:3 1:1,5

GB 1:2

BE 13:15 1:1,15

FR 2:3 1:1,5

DE

3:5

1:1,7

CH 1:1

IT

2:3

1:1,5

FI 11:18 1:1,64

NO 8:11 1:1,375

LV 1:2

PL 5:8 1:1,6

CZ 2:3 1:1,5

GR 2:3 1:1,5

CY 3:5 1:1,7

SE 10:16 1:1,6

DK 28:37 1:1,32

AT 2:3 1:1,5

HU 1:2

RO 2:3 1:1,5

RS 2:3 1:1,5

BG

3:5

1:1,7

IE 1:2

LU

1:2 (of 3:5)

EG

2:3

1:1,5

NZ 1:2

RU 2:3

MD 1:2

EU 2:3 1:1,5

Land Verhouding

vlag vlag+outline kleurcodes

Vlaggen (v.2015)

C-M-Y-K:

0-84-77-32

C-M-Y-K:

0-0-0-0

Pantone

032-C

C-M-Y-K:

0-0-0-0

C-M-Y-K:

76-50-0-46

C-M-Y-K:

100-72-0-18.5

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-91-76-6

C-M-Y-K:

100-72-0-18.5

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-91-76-6

C-M-Y-K:

0-0-0-100

C-M-Y-K:

0-15-95-0

C-M-Y-K:

0-90-80-5

C-M-Y-K:

100-70-0-5

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-90-86-0

C-M-Y-K:

0-0-0-100

C-M-Y-K:

0-100-100-0

C-M-Y-K:

0-12-100-5

Pantone

144-C

Pantone

336-C

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-100-100-0

C-M-Y-K:

0-0-0-0

C-M-Y-K:

100-0-100-45

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-100-100-0

C-M-Y-K:

100-70-0-10

C-M-Y-K:

0-10-95-0

C-M-Y-K:

0-90-80-5

Pantone

186-C

Pantone

116-C

C-M-Y-K:

0-0-0-100

C-M-Y-K:

100-70-0-10

C-M-Y-K:

0-10-95-0

C-M-Y-K:

0-90-80-5

C-M-Y-K:

100-70-0-10

C-M-Y-K:

0-10-95-0

C-M-Y-K:

0-90-80-5

Pantone

347-C

Pantone

151

RGB:

255-255-255

RGB:

0-150-110

RGB:

214-38-18

Pantone

032-C

C-M-Y-K:

0-0-0-0

Pantone

299

C-M-Y-K:

100-56-0-18.5

C-M-Y-K:

0-0-0-0

Pantone Red

032 U

C-M-Y-K:

0-0-0-0

Pantone Red

281 U

C-M-Y-K:

25-96-84-19

C-M-Y-K:

0-0-0-0

Pantone

186-C

C-M-Y-K:

0-0-0-0

C-M-Y-K:

0-0-0-0

Pantone

348-C

#: D4 21 3D

ca.10-96-71-1

#: E9 E8 E7

NCS

0580-Y10R

NCS

4055-R95B

Pantone

281 U

Pantone Red

032 U

C-M-Y-K:

0-0-0-0

C-M-Y-K:

ca.98-99-22-14

C-M-Y-K:

0-0-0-0

Pantone

186-C

C-M-Y-K:

0-0-0-0

C-M-Y-K:

100-80-0-0

C-M-Y-K:

0-0-100-0

3/2

2/9

1

1

3/2

30°

2/3

DESIGN GUIDE

Mandatory Requirements

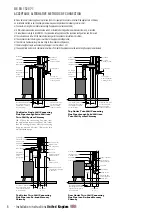

Connection to an appliance which is not connected to the fuel supply, should be carried out by a competent person� We recommend the use of HETAS approved installers for

solid fuel applications� If installation is carried out by a non HETAS registered installer, the installation must be certified by a local Building Control inspector� Connection to an

appliance that is connected to the fuel supply must be carried out by a Gas Safe (Gas) or OFTEC (Oil) registered installer�

The design guide must be read in conjunction with the detailed component installation instructions� For full design and installation details the key referral documents are:

• BS EN 1856-1

: Chimneys - System Chimney Products

• BS EN 1856-2

: Connecting Flue Pipes

• BS EN 1859

: Metal Chimneys - Testing Methods

• BS EN 1443

: Chimneys - General Requirements

• BS EN 15287-1

: Chimneys� Design, installation and commissioning of chimneys� Chimneys for non-room sealed heating appliances�

• BS 5440-1

: Fluing and ventilation for gas appliances of rated input not exceeding 70kW net (1st, 2nd and 3rd family gases)�

Specification for installation of gas appliances to chimneys and for maintenance of chimneys�

• Approved Document J

: - Combustion appliances and fuel storage systems (England & Wales)

• DFP Technical Booklet L

: - Combustion appliances and fuel storage systems (NI)

• Technical Handbook (Domestic & Non Domestic), Section 3

- Environment (Scotland)

• Appliance Installation Instructions

and related standards� Other standards covering specific applications will also be relevant and must be adhered to�

Planning permission may be required, and reference should be made to the local Building Control Department�

Ensure all chimney components are available and check them to ensure there has been no damage� Do not use damaged components� Build the chimney up through the

previous designed route which should be as straight as possible�

PRIOR TO INSTALLATION

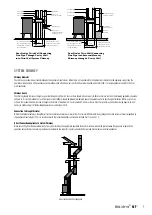

Ventilation

It is very important that sufficient air for combustion and ventilation is provided to the room containing the appliance, to enable correct and efficient working of the appliance

and chimney system� Reference should be made to the appliance manufacturer’s instructions and recommendations are also given in the Building Regulations Document J,

CIBSE guidance notes and BS 5440�

Carbon Monoxide Alarms

The carbon monoxide alarms should comply with BS EN 50291

Where a new or replacement fixed solid fuel appliance is installed in a dwelling, a carbon monoxide alarm must be provided

in the room where the appliance is located�

Please follow manufacturers instructions with regards to siting and fixing or alternatively :-

a) On the ceiling at least 300mm from any wall or if it is located on a wall, as high up as possible (above any doors and windows), but not within 150mm of the ceiling and

b) between 1m and 3m horizontally from the appliance�

N�B Provision of a carbon monoxide alarm should not be regarded as a substitute for correct installation and regular servicing�

Painting

If painting of any external sections is required, it is important to de-grease, dry and prime the exterior surface prior to the application of appropriate heat resistant paint�

Handling

It is advised that suitable PPE should be used when handling the products�

Delivery to Site and Storage

Components should be carefully transported and off loaded� They should be inspected to ensure they have not been damaged, and should be stored off the ground and under

cover so that they are protected from accidental damage and the adverse effects of weather�

Pools/Coastal areas/etc.

The use of stainless steel systems in an enclosed space where there may be a high concentration of aggressive vapours and acid in the air (such as in swimming pools,

launderettes, etc�) may cause a problem� This also applies to installation in the immediate vicinity of the sea and/or with a view of the sea�

4

- Installation instructions

United Kingdom